Table of Contents

Benefits of Using Black Annealed Steel Tube in Structural Applications

Black annealed steel tube is a popular choice for structural applications due to its durability, strength, and versatility. This type of steel tube is made by heating the steel to a high temperature and then cooling it slowly to create a soft, ductile material that is easy to work with. The black annealed finish gives the steel tube a sleek, professional look that is perfect for a wide range of applications.

One of the main benefits of using black annealed steel tube in structural applications is its strength. This type of steel tube is able to withstand heavy loads and high pressure, making it ideal for use in construction projects, manufacturing facilities, and other applications where strength is essential. Additionally, black annealed steel tube is resistant to corrosion, making it a long-lasting and cost-effective option for structural applications.

Another benefit of using black annealed steel tube is its versatility. This type of steel tube can be easily welded, bent, and shaped to fit a wide range of applications. Whether you need a straight piece of tubing or a custom shape, black annealed steel tube can be easily manipulated to meet your specific needs. Additionally, black annealed steel tube is available in a variety of sizes and thicknesses, making it easy to find the perfect option for your project.

In addition to its strength and versatility, black annealed steel tube is also easy to work with. This type of steel tube can be cut to size using a variety of tools, including saws, torches, and Plasma Cutters. Additionally, black annealed steel tube can be easily drilled, punched, and machined to create custom shapes and designs. This makes it a popular choice for architects, engineers, and designers who need a material that is easy to work with and can be customized to meet their specific requirements.

One of the key features of black annealed steel tube is its bevel ends. Bevel ends are cut at an angle to create a smooth, seamless transition between two pieces of tubing. This not only enhances the appearance of the steel tube but also improves its structural integrity. Bevel ends help to distribute stress evenly across the joint, reducing the risk of cracking, bending, or other forms of damage. This makes black annealed steel tube with bevel ends an ideal choice for applications where strength and durability are essential.

Overall, black annealed steel tube is a versatile, durable, and cost-effective option for a wide range of structural applications. Its strength, versatility, and ease of use make it a popular choice for construction projects, manufacturing facilities, and other applications where quality and reliability are essential. Whether you need a straight piece of tubing or a custom shape, black annealed steel tube with bevel ends is a reliable and efficient option that will meet your needs and exceed your expectations.

How to Properly Maintain and Extend the Lifespan of Hot Rolled Carbon Structure Seamless Steel Pipe with Bevel Ends

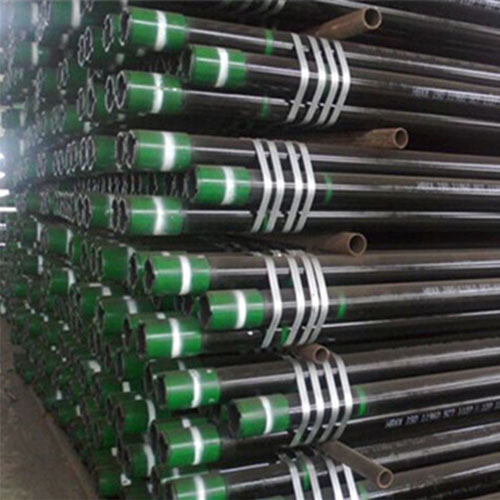

Hot rolled carbon structure seamless Steel Pipes with bevel ends are a popular choice in various industries due to their durability and strength. However, like any other material, these pipes require proper maintenance to ensure their longevity and optimal performance. In this article, we will discuss some essential tips on how to properly maintain and extend the lifespan of hot rolled carbon structure seamless steel pipes with bevel ends.

First and foremost, it is crucial to regularly inspect the pipes for any signs of damage or wear. Look for cracks, dents, or corrosion on the surface of the pipes, as these can weaken the structure and Lead to potential leaks or failures. If any issues are detected, it is important to address them promptly to prevent further damage.

In addition to visual inspections, it is also recommended to perform regular cleaning of the pipes. Dirt, debris, and other contaminants can accumulate on the surface of the pipes over time, leading to corrosion and deterioration. Use a mild detergent and a soft brush to clean the pipes, and rinse them thoroughly with water to remove any residue. Avoid using harsh Chemicals or abrasive materials, as these can damage the surface of the pipes.

Furthermore, it is essential to protect the pipes from environmental factors that can accelerate corrosion and deterioration. Store the pipes in a dry, well-ventilated area to prevent moisture buildup, which can lead to rust and corrosion. Additionally, avoid exposing the pipes to extreme temperatures or harsh chemicals, as these can weaken the material and compromise its integrity.

Another important aspect of maintaining hot rolled carbon structure seamless steel pipes with bevel ends is proper handling and installation. When Transporting the pipes, use appropriate lifting equipment and secure them properly to prevent damage. During installation, ensure that the pipes are properly aligned and supported to prevent stress and strain on the material. Follow the manufacturer’s guidelines and recommendations for installation to ensure the pipes are installed correctly.

Regular maintenance and inspection of the pipes are essential to identify any potential issues and address them before they escalate. Keep a record of maintenance activities and inspections to track the condition of the pipes over time. This will help you identify any patterns or trends that may indicate a need for repairs or replacements.

In conclusion, proper maintenance is key to extending the lifespan of hot rolled carbon structure seamless steel pipes with bevel ends. By regularly inspecting, cleaning, and protecting the pipes, as well as handling and installing them correctly, you can ensure their longevity and optimal performance. Remember to follow the manufacturer’s guidelines and recommendations for maintenance to keep your pipes in top condition. With proper care and maintenance, your hot rolled carbon structure seamless steel pipes with bevel ends will continue to serve you well for years to come.