Table of Contents

Benefits of Using Steel Wire Rope with Loops for Heavy-Duty Lifting Applications

Steel wire rope with loops is a versatile and reliable tool for heavy-duty lifting applications. Whether you are working in construction, mining, or any other industry that requires lifting heavy loads, steel wire rope with loops can provide the strength and durability needed to get the job done safely and efficiently.

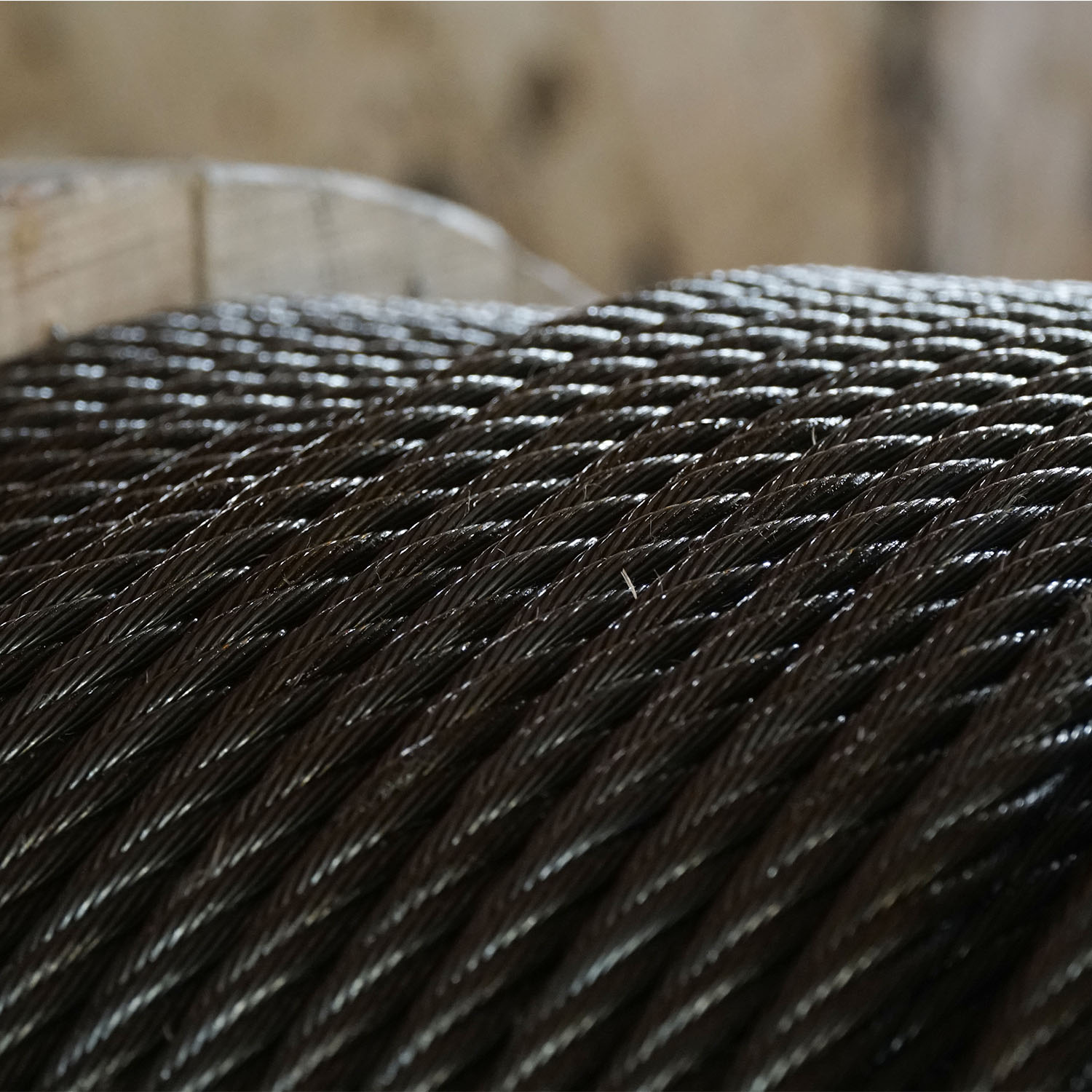

One of the key benefits of using steel wire rope with loops is its high tensile strength. Steel wire rope is made from multiple strands of steel wire twisted together to form a strong and flexible cable. This construction allows steel wire rope to withstand heavy loads without stretching or breaking, making it ideal for lifting applications where Safety is paramount.

In addition to its high tensile strength, steel wire rope with loops is also highly resistant to abrasion and corrosion. This means that it can withstand harsh environmental conditions, such as exposure to moisture, Chemicals, and extreme temperatures, without deteriorating or losing its strength. This makes steel wire rope with loops a reliable choice for lifting applications in a wide range of industries.

Another benefit of using steel wire rope with loops is its versatility. Steel wire rope can be easily customized to fit the specific needs of your lifting application. Whether you need a rope with a certain diameter, length, or configuration of loops, steel wire rope can be tailored to meet your requirements. This flexibility makes steel wire rope with loops a practical choice for a variety of lifting tasks.

Furthermore, steel wire rope with loops is easy to install and maintain. The loops at the ends of the rope make it simple to attach to Hooks, Pulleys, or other lifting equipment, allowing for quick and secure connections. Additionally, steel wire rope requires minimal maintenance to keep it in good working condition, saving you time and money in the long run.

When it comes to safety, steel wire rope with loops is a reliable choice for heavy-duty lifting applications. The high tensile strength and durability of steel wire rope make it less likely to fail under heavy loads, reducing the risk of accidents and injuries. Additionally, the loops at the ends of the rope provide a secure attachment point for lifting equipment, further enhancing safety during lifting operations.

In conclusion, steel wire rope with loops is a practical and reliable choice for heavy-duty lifting applications. Its high tensile strength, resistance to abrasion and corrosion, versatility, ease of installation and maintenance, and safety features make it an ideal tool for lifting heavy loads in a variety of industries. Whether you are working in construction, mining, or any other field that requires lifting heavy objects, steel wire rope with loops can provide the strength and durability needed to get the job done safely and efficiently.

How to Properly Maintain and Inspect Steel Wire Rope with Loops for Safety and Longevity

Steel wire rope with loops is a versatile and durable tool used in a variety of industries, including construction, mining, and transportation. It is essential to properly maintain and inspect steel wire rope with loops to ensure safety and longevity. Neglecting to do so can result in accidents, injuries, and costly downtime. In this article, we will discuss the importance of maintaining and inspecting steel wire rope with loops, as well as provide some tips on how to do so effectively.

Regular maintenance and inspection of steel wire rope with loops is crucial for ensuring its safe and efficient operation. Over time, wear and tear can weaken the rope, leading to potential failure. By conducting regular inspections, any signs of damage or wear can be identified and addressed before they become a safety hazard. Additionally, proper maintenance can extend the lifespan of the rope, saving time and money in the long run.

When inspecting steel wire rope with loops, it is important to look for any signs of wear, such as broken wires, kinks, or distortion. These can indicate that the rope is nearing the end of its useful life and should be replaced. It is also important to check for any signs of corrosion, as this can weaken the rope and make it more prone to failure. In addition to visual inspections, it is also important to feel for any abnormalities, such as lumps or bumps, which can indicate internal damage.

In addition to regular inspections, proper maintenance of steel wire rope with loops is essential for ensuring its longevity. This includes keeping the rope clean and free of debris, as well as lubricating it regularly to prevent corrosion and reduce friction. It is also important to store the rope properly when not in use, as exposure to the elements can accelerate wear and tear.

When it comes to maintaining and inspecting steel wire rope with loops, it is important to follow the manufacturer’s guidelines and recommendations. This may include specific inspection intervals, as well as guidelines for lubrication and storage. It is also important to keep detailed records of inspections and maintenance, as this can help identify any patterns or trends in wear and tear, and ensure that the rope is being properly cared for.

In conclusion, proper maintenance and inspection of steel wire rope with loops is essential for ensuring its safety and longevity. By conducting regular inspections and following the manufacturer’s guidelines for maintenance, the risk of accidents and injuries can be minimized, and the lifespan of the rope can be extended. It is important to take the time to properly care for steel wire rope with loops, as neglecting to do so can have serious consequences. By following these tips, you can ensure that your steel wire rope with loops remains in good condition and continues to serve its intended purpose safely and effectively.