Table of Contents

Benefits of Using Alloy Boiler Pipe in Industrial Applications

Alloy boiler pipes are an essential component in industrial applications, providing a reliable and efficient means of Transporting fluids and gases at high temperatures and pressures. These pipes are made from a variety of materials, including Carbon Steel, Stainless Steel, and Alloy Steel, each offering unique properties that make them suitable for specific applications. In this article, we will explore the benefits of using alloy boiler pipes in industrial settings and why they are preferred over other types of piping materials.

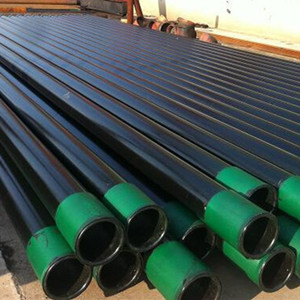

One of the primary advantages of alloy boiler pipes is their high strength and durability. These pipes are designed to withstand extreme temperatures and pressures, making them ideal for use in industrial Boilers, power plants, and other high-temperature applications. The use of alloy materials also helps to prevent corrosion and rusting, ensuring the longevity and reliability of the piping system.

https://www.youtube.com/watch?v=6tUfn1bKo9YIn addition to their strength and durability, alloy boiler pipes are also highly resistant to wear and tear. This makes them an excellent choice for applications where the pipes are subjected to high Levels of stress and abrasion, such as in chemical processing plants and oil refineries. The smooth surface of alloy pipes also helps to reduce friction and improve the flow of fluids, resulting in increased efficiency and reduced energy consumption.

Another benefit of using alloy boiler pipes is their versatility and flexibility. These pipes can be easily customized to meet the specific requirements of a particular application, including size, shape, and thickness. This flexibility allows for greater design freedom and ensures that the piping system can be tailored to the unique needs of the industrial process.

Furthermore, alloy boiler pipes are easy to install and maintain, reducing downtime and operational costs. The seamless construction of these pipes eliminates the need for welding, which can weaken the structure and increase the risk of leaks. Additionally, the smooth surface of alloy pipes makes them easy to clean and inspect, ensuring that the piping system remains in optimal condition.

In conclusion, alloy boiler pipes offer a wide range of benefits for industrial applications, including high strength, durability, resistance to wear and tear, versatility, and ease of installation and maintenance. These pipes are an essential component in industrial processes that require the transportation of fluids and gases at high temperatures and pressures. By choosing alloy boiler pipes from a reputable manufacturer, such as Galvanized Us American Standard Carbon Seamless Steel Tube Factory, industrial companies can ensure the reliability and efficiency of their piping systems for years to come.

Importance of Galvanizing in Extending the Lifespan of Steel Tubes

Steel tubes are a crucial component in various industries, including construction, manufacturing, and transportation. They are used for a wide range of applications, from carrying fluids and gases to providing structural support. However, steel tubes are susceptible to corrosion, which can significantly reduce their lifespan and compromise their performance. To combat this issue, many steel tube manufacturers offer galvanized steel tubes, which are coated with a protective layer of Zinc to prevent corrosion.

Galvanizing is a process that involves immersing steel tubes in a bath of molten zinc, which forms a metallurgical bond with the steel surface. This protective zinc coating acts as a barrier against corrosive elements such as moisture, Chemicals, and saltwater, extending the lifespan of the steel tubes and ensuring their durability in harsh environments. In addition to protecting against corrosion, galvanized steel tubes also have a higher resistance to impact and abrasion, making them ideal for applications that require strength and longevity.

One of the key benefits of galvanized steel tubes is their low maintenance requirements. Unlike untreated steel tubes, which require regular painting or coating to prevent corrosion, galvanized steel tubes are virtually maintenance-free. This not only saves time and money but also reduces the risk of premature failure due to neglect or improper maintenance. By choosing galvanized steel tubes, industries can enjoy peace of mind knowing that their infrastructure is protected against corrosion and will last for years to come.

In the United States, American Standard Carbon Seamless Steel Tube Factory is a leading manufacturer of galvanized steel tubes. Their alloy boiler pipe galvanized steel tubes are manufactured to meet the highest quality standards and are designed to withstand the rigors of industrial applications. With a focus on innovation and customer satisfaction, American Standard Carbon Seamless Steel Tube Factory is committed to providing reliable and durable steel tubes that meet the needs of their customers.

The importance of galvanizing in extending the lifespan of steel tubes cannot be overstated. By choosing galvanized steel tubes, industries can ensure the longevity and performance of their infrastructure, reducing the risk of costly repairs and replacements. Whether used in construction, manufacturing, or transportation, galvanized steel tubes offer a cost-effective and reliable solution for protecting against corrosion and ensuring the durability of Steel Structures.

In conclusion, galvanized steel tubes play a crucial role in extending the lifespan of steel structures and ensuring their performance in harsh environments. With their protective zinc coating and high resistance to corrosion, galvanized steel tubes offer a durable and low-maintenance solution for a wide range of industrial applications. American Standard Carbon Seamless Steel Tube Factory is a trusted manufacturer of galvanized steel tubes, providing high-quality products that meet the needs of their customers. By choosing galvanized steel tubes, industries can enjoy the benefits of long-lasting and reliable infrastructure that is protected against corrosion and built to last.

Comparison of American Standard Carbon Seamless Steel Tubes from Different Manufacturers

Alloy boiler pipes are an essential component in various industrial applications, particularly in the heating and cooling systems of boilers. These pipes are designed to withstand high temperatures and pressures, making them crucial for the efficient operation of boilers. When it comes to choosing the right alloy boiler pipe, it is important to consider the quality and standards of the product.

One of the most popular choices for alloy boiler pipes is the American Standard Carbon Seamless Steel Tube. This type of pipe is known for its durability, strength, and resistance to corrosion. Many manufacturers produce American Standard Carbon Seamless Steel Tubes, each with its own unique specifications and quality standards.

When comparing American Standard Carbon Seamless Steel Tubes from different manufacturers, it is important to consider several factors. One of the key considerations is the material used in the production of the pipes. High-quality alloy boiler pipes are typically made from carbon steel, which offers excellent strength and durability. It is important to ensure that the pipes are made from high-quality materials to ensure their longevity and performance.

In addition to the material used, the manufacturing process also plays a crucial role in determining the quality of American Standard Carbon Seamless Steel Tubes. Different manufacturers may use different techniques and processes to produce these pipes, which can impact their overall quality. It is important to choose a manufacturer that follows strict quality control measures and adheres to industry standards to ensure the pipes meet the necessary requirements.

Another important factor to consider when comparing American Standard Carbon Seamless Steel Tubes from different manufacturers is the galvanization process. Galvanization is a common method used to protect Steel Pipes from corrosion and rust. It involves coating the pipes with a layer of zinc, which acts as a barrier against environmental elements. The quality of the galvanization process can vary between manufacturers, so it is important to choose a manufacturer that uses high-quality galvanization techniques to ensure the pipes are well-protected.

Furthermore, the size and dimensions of the American Standard Carbon Seamless Steel Tubes are also important considerations when comparing products from different manufacturers. It is essential to choose pipes that are the right size and thickness for the specific application to ensure optimal performance and efficiency. Different manufacturers may offer pipes in varying sizes and dimensions, so it is important to carefully review the specifications before making a decision.

When selecting a manufacturer for American Standard Carbon Seamless Steel Tubes, it is crucial to consider their reputation and track record in the industry. A reputable manufacturer with a history of producing high-quality products is more likely to provide reliable and durable alloy boiler pipes. It is also important to consider factors such as pricing, delivery times, and customer service when choosing a manufacturer.

In conclusion, American Standard Carbon Seamless Steel Tubes are an excellent choice for alloy boiler pipes due to their durability, strength, and resistance to corrosion. When comparing products from different manufacturers, it is important to consider factors such as the material used, manufacturing process, galvanization techniques, size and dimensions, and the manufacturer’s reputation. By carefully evaluating these factors, you can choose the best American Standard Carbon Seamless Steel Tubes for your specific application.