Table of Contents

The Importance of Quality Control in SAE1010 Brake Pads Back Plates Production

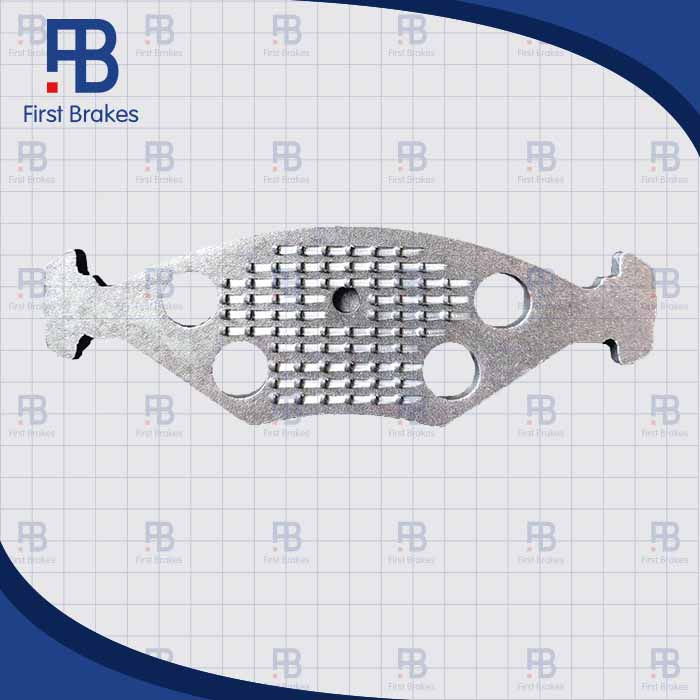

Quality control is a critical aspect of any manufacturing process, especially when it comes to producing components for automotive applications. One such component that requires stringent quality control measures is the back plate of SAE1010 brake pads. These back plates play a crucial role in the overall performance and Safety of the brake system, making it essential to ensure that they meet the highest standards of quality and reliability.

At the SAE1010 brake pads back plates producing factory, quality control is a top priority. The production process begins with the selection of high-quality SAE1010 steel, which is known for its excellent strength and durability. This raw material undergoes rigorous testing to ensure that it meets the required specifications for the production of brake pads back plates.

Once the raw material has been approved, it is then processed using state-of-the-art machinery and equipment. Each step of the manufacturing process is closely monitored by skilled technicians who are trained to identify any potential defects or deviations from the desired quality standards. This level of attention to detail is essential to ensure that the finished back plates meet the strict requirements set forth by automotive manufacturers.

Throughout the production process, samples of the back plates are taken at regular intervals for testing and inspection. These samples are subjected to a series of tests to evaluate their mechanical properties, dimensional accuracy, and surface finish. Any back plates that do not meet the specified criteria are immediately rejected and sent back for rework or disposal.

In addition to in-process testing, the finished back plates undergo a final inspection before they are approved for shipment. This final inspection involves a thorough examination of each back plate to check for any defects or imperfections that may have been missed during the production process. Only back plates that pass this final inspection are deemed suitable for use in automotive brake systems.

The importance of quality control in the production of SAE1010 brake pads back plates cannot be overstated. These components are critical to the safe operation of vehicles, and any defects or failures could have serious consequences. By implementing strict quality control measures throughout the production process, the SAE1010 brake pads back plates producing factory ensures that only the highest quality components are delivered to customers.

In conclusion, quality control is an essential aspect of manufacturing SAE1010 brake pads back plates. By maintaining strict quality control measures throughout the production process, the SAE1010 brake pads back plates producing factory ensures that only the highest quality components are produced. This commitment to quality and reliability is essential to the safety and performance of automotive brake systems, making it a top priority for manufacturers in the automotive industry.