Table of Contents

Benefits of Using High Quality C95/T95/P110/Q125 Oil Casing Pipe

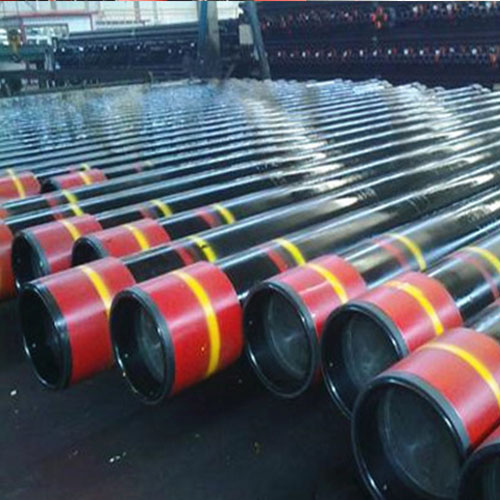

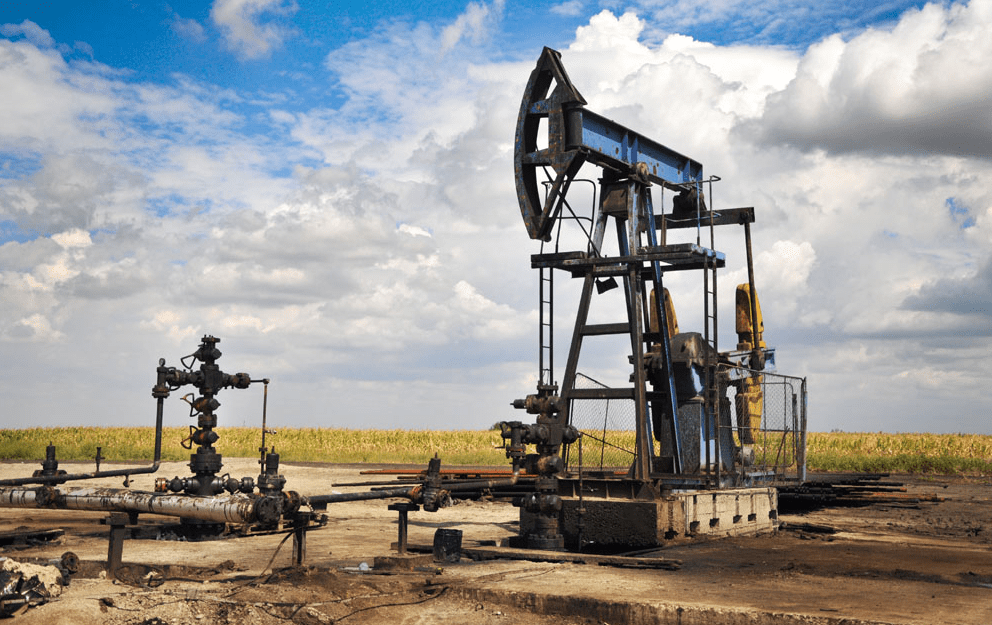

Oil casing pipes are an essential component in the oil and gas industry, used to protect and support the wellbore during drilling and completion operations. The quality of the casing pipe plays a crucial role in ensuring the success and longevity of the well. High-quality casing pipes, such as C95/T95/P110/Q125, offer a range of benefits that make them the preferred choice for oil and gas companies.

One of the key benefits of using high-quality C95/T95/P110/Q125 oil casing pipes is their superior strength and durability. These pipes are made from high-grade steel that has been carefully engineered to withstand the extreme pressures and temperatures encountered in oil and gas wells. This strength and durability help to prevent the casing pipe from collapsing or deforming under the weight of the surrounding rock formations, ensuring the integrity of the wellbore.

In addition to their strength and durability, C95/T95/P110/Q125 oil casing pipes also offer excellent corrosion resistance. The harsh conditions found in oil and gas wells can cause traditional casing pipes to corrode and degrade over time, leading to costly repairs and replacements. High-quality casing pipes are specially treated to resist corrosion, ensuring that they maintain their structural integrity and performance over the long term.

Another benefit of using high-quality C95/T95/P110/Q125 oil casing pipes is their superior performance in challenging drilling environments. These pipes are designed to withstand the high pressures, temperatures, and stresses that are common in deepwater and high-pressure wells. Their advanced design and construction make them the ideal choice for demanding drilling applications, where reliability and performance are paramount.

Furthermore, C95/T95/P110/Q125 oil casing pipes are highly versatile and can be used in a wide range of wellbore configurations. Whether drilling in shallow or deep wells, onshore or offshore, these pipes can be customized to meet the specific requirements of the well. This versatility makes them a cost-effective and efficient choice for oil and gas companies looking to maximize their drilling operations.

In conclusion, the benefits of using high-quality C95/T95/P110/Q125 oil casing pipes are clear. Their superior strength, durability, corrosion resistance, and performance make them the preferred choice for oil and gas companies around the world. By investing in high-quality casing pipes, companies can ensure the success and longevity of their drilling operations, while minimizing the risk of costly repairs and replacements. With their advanced design and construction, C95/T95/P110/Q125 oil casing pipes are the best choice for companies looking to maximize the efficiency and reliability of their drilling operations.

How to Choose the Best Sell High Quality C95/T95/P110/Q125 Oil Casing Pipe for Your Project

When it comes to choosing the best sell high-quality C95/T95/P110/Q125 oil casing pipe for your project, there are several factors to consider. Oil casing pipes are an essential component in the oil and gas industry, as they provide structural support and protection for the wellbore. Selecting the right casing pipe is crucial to the success of your project, as it can impact the overall efficiency and longevity of the well.

One of the first things to consider when choosing a casing pipe is the material it is made from. C95, T95, P110, and Q125 are all grades of steel that are commonly used in oil casing pipes. Each grade has its own unique properties and strengths, so it is important to select the grade that best suits your project’s needs. C95 and T95 are both high-strength steel grades that are suitable for deep well applications, while P110 and Q125 are even higher strength grades that are often used in harsh environments or high-pressure wells.

In addition to the grade of steel, you should also consider the size and weight of the casing pipe. The size of the pipe will depend on the diameter of the wellbore and the depth of the well. It is important to choose a casing pipe that is the right size for your project, as using a pipe that is too small or too large can Lead to structural issues and inefficiencies. The weight of the pipe is also important, as it will impact the overall cost of the project and the ease of installation.

Another important factor to consider when choosing a casing pipe is the threading and connection type. There are several different types of threads and connections available, each with its own advantages and disadvantages. Some common types include API round Thread, API buttress thread, and premium connections. The type of connection you choose will depend on the specific requirements of your project, such as the pressure and temperature conditions of the well.

When selecting a casing pipe, it is also important to consider the manufacturing process and quality control measures of the supplier. High-quality casing pipes are essential for the success of your project, as they will ensure the structural integrity and longevity of the well. Look for suppliers that have a proven track record of producing high-quality casing pipes and have stringent quality control measures in place.

In conclusion, choosing the best sell high-quality C95/T95/P110/Q125 oil casing pipe for your project is a crucial decision that can impact the overall success of your well. Consider factors such as the grade of steel, size and weight of the pipe, threading and connection type, and the manufacturing process of the supplier. By carefully evaluating these factors and selecting a high-quality casing pipe, you can ensure the efficiency and longevity of your wellbore.