Table of Contents

Benefits of Using API 5L Tube in Industrial Applications

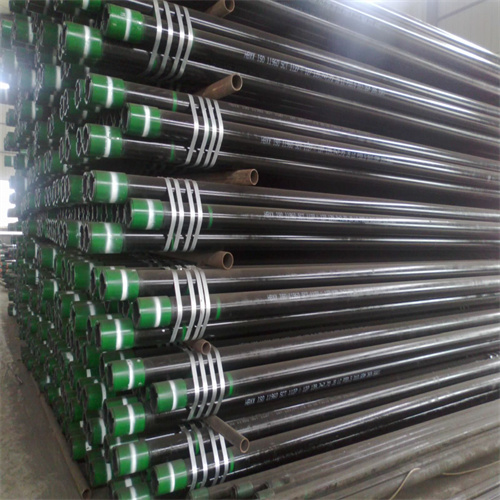

API 5L tube is a type of seamless Carbon Steel pipe that is commonly used in various industrial applications. It is manufactured according to the American Petroleum Institute (API) standards, which ensure high quality and consistency in its production. API 5L tube is available in different grades such as ASTM A53, ASTM A106, A179, A192, and A333, each with its own specific properties and characteristics.

One of the main benefits of using API 5L tube in industrial applications is its high strength and durability. Carbon steel is known for its strength and ability to withstand high temperatures and pressures, making it ideal for use in industries such as oil and gas, petrochemical, and power generation. API 5L tube is designed to meet the rigorous demands of these industries, providing a reliable and long-lasting solution for Transporting fluids and gases.

Another advantage of API 5L tube is its seamless construction, which eliminates the need for welding and reduces the risk of leaks and failures. Seamless pipes are made by piercing a solid billet of steel to create a hollow tube, resulting in a smooth and uniform surface that is free from defects. This seamless construction also allows for better flow of fluids and gases, improving efficiency and reducing energy consumption.

In addition to its strength and seamless construction, API 5L tube is also highly resistant to corrosion and erosion. Carbon steel is naturally resistant to rust and corrosion, making it a cost-effective and low-maintenance option for industrial applications. API 5L tube is also available in different coatings and finishes to further enhance its resistance to environmental factors and extend its service life.

Furthermore, API 5L tube is versatile and can be used in a wide range of applications, from transporting water and Chemicals to carrying steam and air. Its flexibility and adaptability make it a popular choice for various industries that require reliable and efficient piping solutions. Whether it is for underground pipelines, aboveground structures, or offshore installations, API 5L tube can meet the diverse needs of industrial applications.

Overall, API 5L tube offers numerous benefits for industrial applications, including high strength, durability, seamless construction, corrosion resistance, and versatility. Its adherence to API standards ensures quality and consistency in its production, making it a reliable and cost-effective option for transporting fluids and gases in demanding environments. With its proven performance and long service life, API 5L tube is a preferred choice for industries that require high-quality piping solutions.

In conclusion, API 5L tube is a valuable asset for industrial applications that demand strength, durability, and reliability. Its seamless construction, corrosion resistance, and versatility make it an ideal choice for transporting fluids and gases in various industries. By choosing API 5L tube, businesses can benefit from a high-quality and cost-effective piping solution that meets their specific needs and requirements.

Comparison of ASTM A53, ASTM A106, A179, A192, and A333 Hot Rolled Carbon Steel Seamless Pipe

API 5L Tube ASTM A53 ASTM A106 A179 A192 A333 Hot Rolled Carbon Steel Seamless Pipe

When it comes to choosing the right type of carbon steel seamless pipe for your project, it’s important to understand the differences between various grades and specifications. In this article, we will compare five popular options: ASTM A53, ASTM A106, A179, A192, and A333 hot rolled carbon steel seamless pipes.

First, let’s take a look at ASTM A53. This specification covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26. It is commonly used for mechanical and pressure applications, as well as for steam, water, gas, and air lines. ASTM A53 is suitable for welding, flanging, and bending, making it a versatile choice for a wide range of applications.

Next, we have ASTM A106. This specification covers seamless carbon steel pipe for high-temperature service in NPS 1/8 to NPS 48. It is commonly used in refineries, power plants, and chemical plants where high temperatures and pressures are present. ASTM A106 is suitable for bending, flanging, and similar forming operations, making it a popular choice for demanding applications.

Next, we have ASTM A106. This specification covers seamless carbon steel pipe for high-temperature service in NPS 1/8 to NPS 48. It is commonly used in refineries, power plants, and chemical plants where high temperatures and pressures are present. ASTM A106 is suitable for bending, flanging, and similar forming operations, making it a popular choice for demanding applications.

Moving on to ASTM A179, this specification covers minimum-wall thickness, seamless cold-drawn low-carbon steel tubes for Heat Exchangers, condensers, and similar heat transfer apparatus. ASTM A179 is widely used in the manufacturing of heat exchangers due to its excellent thermal conductivity and corrosion resistance. It is a cost-effective option for applications where high heat transfer efficiency is required.

Now, let’s discuss ASTM A192. This specification covers seamless carbon steel boiler tubes for high-pressure service. ASTM A192 is commonly used in power generation plants and industrial Boilers where high pressure and temperature conditions are present. It offers excellent tensile strength and corrosion resistance, making it a reliable choice for demanding applications.

Lastly, we have ASTM A333. This specification covers seamless and welded steel pipe for low-temperature service. ASTM A333 is commonly used in cryogenic applications where low temperatures are present, such as in liquefied Natural Gas (LNG) plants and refrigeration systems. It offers good impact toughness and low-temperature properties, making it suitable for extreme cold environments.

In conclusion, each of these specifications offers unique advantages and is suitable for different applications. ASTM A53 is versatile and widely used for various mechanical and pressure applications. ASTM A106 is ideal for high-temperature service in refineries and power plants. ASTM A179 is cost-effective and efficient for heat exchangers. ASTM A192 is reliable for high-pressure boiler applications. And ASTM A333 is suitable for low-temperature service in cryogenic environments.

When selecting a carbon steel seamless pipe for your project, it’s important to consider the specific requirements and conditions of your application. By understanding the differences between ASTM A53, ASTM A106, A179, A192, and A333, you can make an informed decision that meets your needs and ensures the success of your project.