Table of Contents

Benefits of Using API 5L Carbon Steel Pipe in Industrial Applications

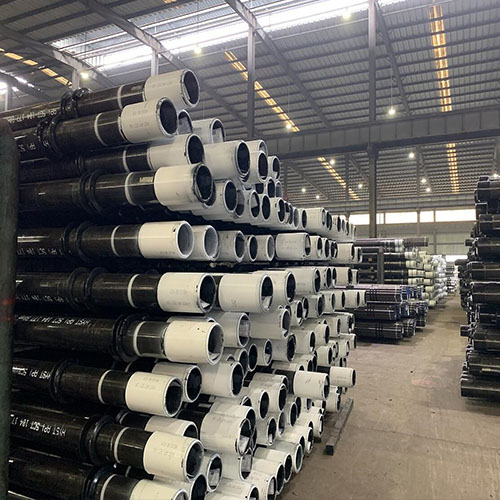

API 5L carbon Steel Pipes are widely used in various industrial applications due to their numerous benefits. These pipes are known for their high strength, durability, and resistance to corrosion, making them ideal for Transporting fluids and gases in a wide range of industries. In this article, we will explore the benefits of using API 5L carbon steel pipes in industrial applications.

One of the key advantages of API 5L carbon steel pipes is their high strength. These pipes are made from high-quality carbon steel, which gives them the strength to withstand high pressure and temperature conditions. This makes them ideal for use in industries such as oil and gas, petrochemical, and power generation, where the pipes are subjected to extreme conditions.

In addition to their high strength, API 5L carbon steel pipes are also highly durable. These pipes are designed to last for many years, even in harsh environments. This durability makes them a cost-effective choice for industrial applications, as they require less maintenance and replacement compared to other types of pipes.

Another benefit of using API 5L carbon steel pipes is their resistance to corrosion. These pipes are coated with a protective layer that prevents rust and corrosion, ensuring that they remain in good condition for a long time. This corrosion resistance is essential in industries where the pipes are exposed to corrosive substances, such as Chemicals or saltwater.

API 5L carbon steel pipes are also known for their versatility. These pipes come in a variety of sizes and specifications, making them suitable for a wide range of industrial applications. Whether you need a small diameter pipe for a residential plumbing project or a large diameter pipe for a major construction project, API 5L carbon steel pipes can meet your requirements.

Furthermore, API 5L carbon steel pipes are easy to install and maintain. These pipes can be welded or threaded together quickly and easily, reducing installation time and costs. Additionally, their low maintenance requirements make them a hassle-free choice for industrial applications.

In conclusion, API 5L carbon steel pipes offer a range of benefits that make them an excellent choice for industrial applications. Their high strength, durability, resistance to corrosion, versatility, and ease of installation and maintenance make them a cost-effective and reliable option for transporting fluids and gases in various industries. Whether you are working in the oil and gas, petrochemical, power generation, or construction industry, API 5L carbon steel pipes are a smart choice for your piping needs.

Comparison of ASTM A53, ASTM A252, AS1163 Carbon Steel Pipes for Various Construction Projects

When it comes to choosing the right carbon steel pipe for construction projects, there are several options available in the market. Among the most commonly used are API5L, ASTM A53, ASTM A252, and AS1163 carbon steel pipes. Each of these pipes has its own unique characteristics and is suitable for different types of construction projects. In this article, we will compare these four types of carbon steel pipes to help you make an informed decision for your next construction project.

API5L carbon steel pipes are widely used in the oil and gas industry due to their high strength and durability. These pipes are manufactured according to the American Petroleum Institute (API) standards and are suitable for transporting oil, gas, and other fluids under high pressure. API5L pipes are available in various grades, such as A, B, X42, X46, X52, X56, X60, X65, X70, X80, and X100, depending on the application requirements.

ASTM A53 carbon steel pipes are another popular choice for construction projects. These pipes are manufactured according to the American Society for Testing and Materials (ASTM) standards and are suitable for general structural applications. ASTM A53 pipes are available in three grades: A, B, and C, with grade B being the most commonly used for structural purposes. These pipes are also suitable for use in pressure systems and mechanical applications.

https://youtube.com/watch?v=rTocuyc3QW0ASTM A252 carbon steel pipes are specifically designed for piling and structural applications. These pipes are manufactured according to the ASTM A252 standard and are suitable for driving into the ground to create deep foundations for buildings, bridges, and other structures. ASTM A252 pipes are available in three grades: 1, 2, and 3, with grade 3 being the most commonly used for piling applications. These pipes are also suitable for use in marine construction and other underwater applications.

AS1163 carbon steel pipes are commonly used in Australia and New Zealand for structural and construction purposes. These pipes are manufactured according to the Australian Standard AS1163 and are suitable for a wide range of applications, including building construction, infrastructure projects, and industrial applications. AS1163 pipes are available in various grades, such as C250, C350, and C450, depending on the application requirements.

In terms of manufacturing process, API5L and ASTM A53 carbon steel pipes are typically produced using the electric resistance welding (ERW) process, which involves forming the pipe from a flat sheet of steel and welding the edges together. On the other hand, ASTM A252 and AS1163 carbon steel pipes are usually produced using the submerged arc welding (Saw) process, which involves forming the pipe from a steel plate and welding the seams using a submerged arc welding technique.

In conclusion, when choosing a carbon steel pipe for your construction project, it is important to consider the specific requirements of the application, such as the type of project, the operating conditions, and the structural design. API5L, ASTM A53, ASTM A252, and AS1163 carbon steel pipes each have their own unique characteristics and are suitable for different types of construction projects. By understanding the differences between these pipes, you can make an informed decision and select the right carbon steel pipe for your next construction project.