Table of Contents

Benefits of Using Warm Paving Asphalt Additives in Pavement Construction

Asphalt is a commonly used material in pavement construction due to its durability and ability to withstand heavy traffic loads. However, traditional hot mix asphalt (HMA) can be challenging to work with, as it needs to be heated to high temperatures before it can be applied. This process can be time-consuming and energy-intensive, leading to increased costs and environmental impact.

To address these challenges, warm mix asphalt (WMA) technology has been developed, which allows for the production and placement of asphalt at lower temperatures compared to HMA. This technology has gained popularity in recent years due to its numerous benefits, including improved workability, reduced energy consumption, and lower emissions.

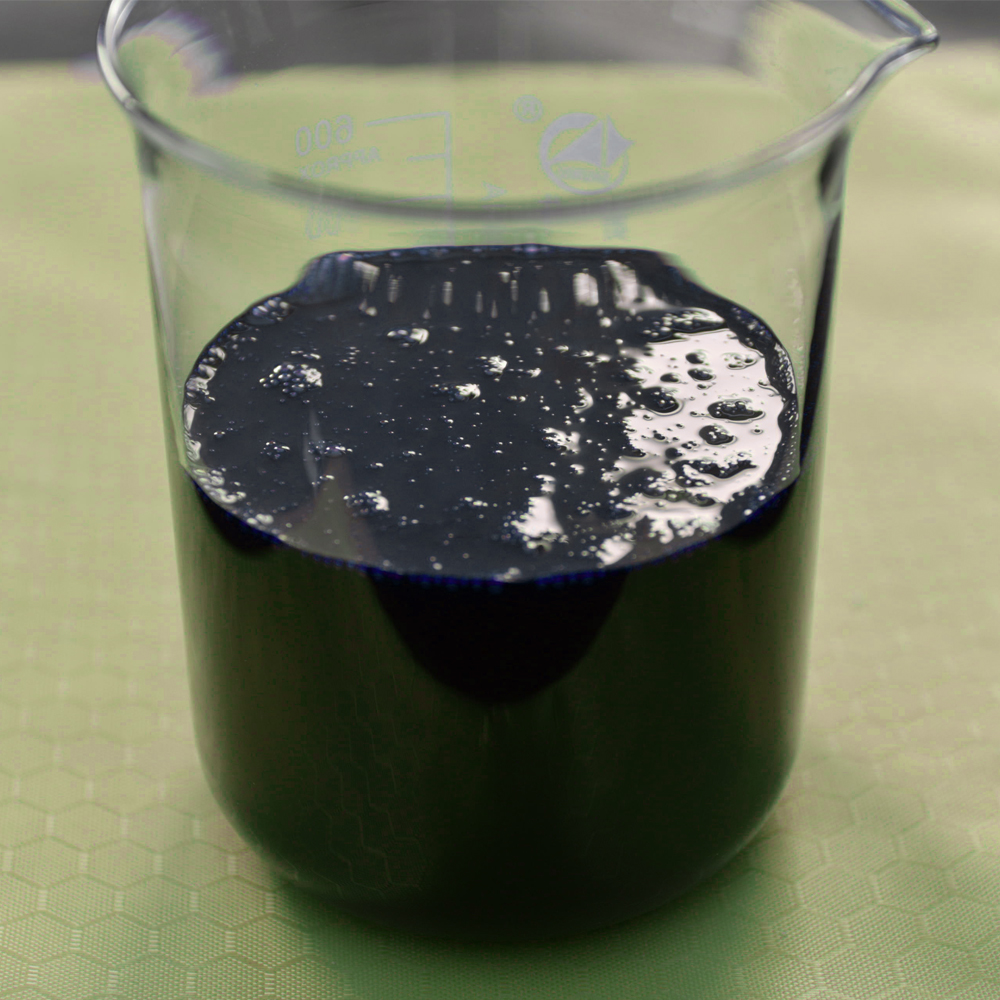

One key component of WMA technology is the use of warm paving asphalt additives, which are mixed with the asphalt binder to lower its viscosity and improve workability at lower temperatures. These additives can be organic or chemical-based and are designed to enhance the performance of the asphalt mixture while reducing its environmental impact.

One of the main benefits of using warm paving asphalt additives is the improved workability of the asphalt mixture. By lowering the viscosity of the binder, these additives make it easier to mix and compact the asphalt at lower temperatures. This results in a smoother and more uniform pavement surface, which can help reduce the occurrence of cracks and potholes over time.

In addition to improved workability, warm paving asphalt additives also help reduce energy consumption during the production and placement of asphalt. Since WMA can be produced and placed at lower temperatures compared to HMA, less energy is required to heat the asphalt mixture, leading to cost savings and reduced greenhouse gas emissions.

Furthermore, warm paving asphalt additives can improve the overall quality of the pavement by enhancing its resistance to rutting, cracking, and moisture damage. These additives can help increase the durability and lifespan of the pavement, resulting in lower maintenance costs and longer service life.

Another advantage of using warm paving asphalt additives is their environmental benefits. By reducing energy consumption and emissions during the production and placement of asphalt, these additives help minimize the environmental impact of pavement construction. This is especially important in today’s world, where sustainability and environmental stewardship are becoming increasingly important considerations in infrastructure projects.

Overall, warm paving asphalt additives offer a range of benefits for pavement construction, including improved workability, reduced energy consumption, enhanced pavement quality, and environmental sustainability. As the demand for more sustainable and cost-effective pavement solutions continues to grow, the use of warm mix asphalt technology and additives is likely to become more widespread in the construction industry. By incorporating these additives into pavement projects, contractors and engineers can achieve better pavement quality while also reducing their environmental footprint.

How Warm Paving Asphalt Additives Improve Pavement Durability and Performance

Warm paving asphalt additives have become increasingly popular in the construction industry due to their ability to improve pavement durability and performance. These additives are designed to enhance the properties of asphalt, making it more resistant to wear and tear, as well as improving its overall quality. In this article, we will explore the benefits of using warm paving asphalt additives and how they can help create better quality pavements.

One of the key advantages of warm paving asphalt additives is their ability to improve the workability of the asphalt mixture. By adding these additives to the mix, contractors can achieve a more consistent and uniform mixture, which makes it easier to lay and compact the asphalt. This results in a smoother pavement surface that is less prone to cracking and rutting, ultimately leading to a longer-lasting pavement.

| Serial Number | Products |

| 1 | Warm Mix Asphalt (WMA) modifier |

In addition to improving workability, warm paving asphalt additives also help enhance the performance of the pavement. These additives can increase the resistance of the asphalt to fatigue and thermal cracking, which are common issues that can affect the longevity of a pavement. By using warm paving asphalt additives, contractors can create pavements that are better able to withstand the stresses of heavy traffic and harsh weather conditions, resulting in a longer service life for the pavement.

Furthermore, warm paving asphalt additives can also improve the sustainability of pavement construction. By using these additives, contractors can reduce the amount of energy required to produce and lay the asphalt mixture, as well as decrease the emissions of greenhouse gases associated with traditional hot mix asphalt production. This not only helps to reduce the environmental impact of pavement construction but also lowers the overall cost of the project, making it a more cost-effective and sustainable option for contractors.

Another benefit of using warm paving asphalt additives is their ability to improve the overall quality of the pavement. These additives can enhance the strength and durability of the asphalt mixture, resulting in a pavement that is more resistant to cracking, rutting, and other forms of distress. This leads to a smoother and safer pavement surface that requires less maintenance over time, saving both time and money for contractors and road agencies.

Overall, warm paving asphalt additives offer a range of benefits that can help improve the quality and performance of pavements. By enhancing workability, performance, sustainability, and overall quality, these additives provide contractors with a cost-effective and efficient solution for creating durable and long-lasting pavements. As the construction industry continues to evolve, warm paving asphalt additives are likely to play an increasingly important role in the development of high-quality pavements that meet the needs of today’s infrastructure challenges.