Table of Contents

Advantages of Using ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube

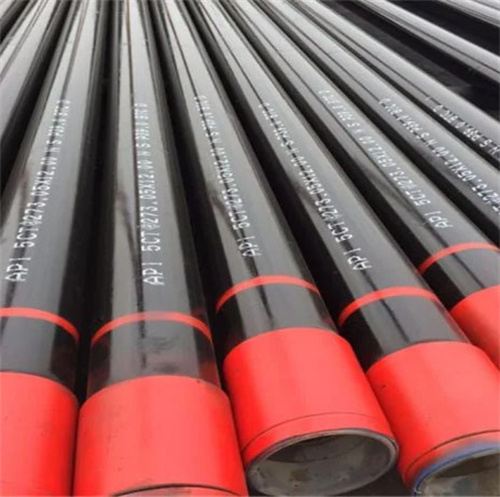

ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube is a popular choice for various industrial applications due to its numerous advantages. This type of carbon steel tube is known for its durability, strength, and versatility, making it a preferred material for construction, manufacturing, and other industries.

One of the key advantages of ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube is its high strength-to-weight ratio. This means that it can withstand heavy loads and pressure without being too heavy or bulky. This makes it an ideal choice for structural applications where strength and durability are essential.

Additionally, ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube is highly resistant to corrosion, making it suitable for use in harsh environments. This type of carbon steel tube is often used in industries such as oil and gas, chemical processing, and marine applications where exposure to corrosive elements is common.

Another advantage of ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube is its ease of fabrication. This material can be easily welded, cut, and shaped to meet specific project requirements. This makes it a cost-effective option for manufacturers and contractors looking to create custom components or structures.

Furthermore, ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube is available in a wide range of sizes and thicknesses, making it suitable for a variety of applications. Whether you need a small diameter tube for a plumbing project or a large diameter tube for a structural application, this material can meet your needs.

In addition to its strength, durability, and versatility, ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube is also cost-effective. Compared to other materials such as Stainless Steel or Aluminum, carbon steel is more affordable, making it a budget-friendly option for projects with tight financial constraints.

Overall, ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube offers numerous advantages that make it a top choice for a wide range of industrial applications. Its high strength-to-weight ratio, corrosion resistance, ease of fabrication, availability in various sizes, and cost-effectiveness make it a versatile and reliable material for construction, manufacturing, and other industries.

In conclusion, ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube is a superior choice for projects that require strength, durability, and versatility. Its numerous advantages make it a popular option for a wide range of industrial applications, from structural components to plumbing systems. If you are looking for a reliable and cost-effective material for your next project, consider using ASTM A53 A106 Q235 Sch40 Schedule 80 Carbon Steel Tube.

Comparison Between Seamless and Welded Carbon Steel Pipes

Carbon steel pipes are widely used in various industries for Transporting fluids and gases. When it comes to choosing between seamless and welded carbon steel pipes, there are several factors to consider. In this article, we will compare the two types of pipes to help you make an informed decision.

Seamless carbon steel pipes are made by piercing a solid billet of steel to create a hollow tube. This process results in a pipe with no seams or welds, making it stronger and more reliable than welded pipes. Seamless pipes are also more uniform in shape and size, which can help improve the flow of fluids through the pipe.

On the other hand, welded carbon steel pipes are made by welding together two pieces of steel to create a pipe. While welded pipes are generally less expensive than seamless pipes, they may not be as strong or reliable. Welded pipes can also be more prone to corrosion and leaks, especially at the weld seams.

One of the main advantages of seamless carbon steel pipes is their strength and durability. Because seamless pipes are made from a single piece of steel, they are less likely to fail under high pressure or temperature. This makes seamless pipes ideal for applications where reliability is crucial, such as in the oil and gas industry.

Welded carbon steel pipes, on the other hand, are more cost-effective and easier to produce in large quantities. Welded pipes can also be manufactured in a variety of sizes and shapes, making them suitable for a wide range of applications. However, welded pipes may require more maintenance and repairs over time, which can increase their overall cost.

In terms of performance, seamless carbon steel pipes are generally preferred for high-pressure and high-temperature applications. Seamless pipes have a smooth interior surface, which can help reduce friction and improve the flow of fluids through the pipe. This can result in lower energy consumption and improved efficiency in industrial processes.

https://www.youtube.com/watch?v=OGeQJl_FZDA

Welded carbon steel pipes, on the other hand, may be more suitable for low-pressure and low-temperature applications. Welded pipes are also easier to customize and modify, making them a versatile option for a variety of projects. However, welded pipes may not be as durable or reliable as seamless pipes in demanding environments.

In conclusion, both seamless and welded carbon steel pipes have their own advantages and disadvantages. The choice between the two types of pipes will ultimately depend on your specific needs and requirements. If you require a strong and reliable pipe for high-pressure applications, seamless carbon steel pipes may be the best option. However, if cost-effectiveness and versatility are more important to you, welded carbon steel pipes may be the better choice. Ultimately, it is important to carefully consider your options and consult with a professional before making a decision.

Applications of ASTM A106 Gr. B BS, DIN, GB, JIS St45 DN15 A333 A335 Carbon Steel Pipes

ASTM A106 Gr. B BS, DIN, GB, JIS St45 DN15 A333 A335 carbon steel pipes are widely used in various industries due to their excellent properties and versatility. These pipes are known for their high strength, durability, and resistance to corrosion, making them ideal for a wide range of applications.

One of the primary applications of ASTM A106 Gr. B BS, DIN, GB, JIS St45 DN15 A333 A335 carbon steel pipes is in the oil and gas industry. These pipes are commonly used for transporting oil, gas, and other fluids over long distances. Their high strength and durability make them suitable for withstanding high pressure and harsh environmental conditions, ensuring the safe and efficient transportation of these valuable resources.

In addition to the oil and gas industry, ASTM A106 Gr. B BS, DIN, GB, JIS St45 DN15 A333 A335 carbon steel pipes are also widely used in the construction industry. These pipes are commonly used for structural applications, such as building frames, bridges, and other infrastructure projects. Their high strength-to-weight ratio makes them an ideal choice for supporting heavy loads and withstanding the stresses of construction.

Another important application of ASTM A106 Gr. B BS, DIN, GB, JIS St45 DN15 A333 A335 carbon steel pipes is in the manufacturing industry. These pipes are commonly used for conveying fluids and gases in industrial processes, such as chemical processing, power generation, and manufacturing. Their resistance to corrosion and high temperatures make them suitable for handling a wide range of Chemicals and operating conditions.

Furthermore, ASTM A106 Gr. B BS, DIN, GB, JIS St45 DN15 A333 A335 carbon steel pipes are also used in the automotive industry. These pipes are commonly used for exhaust systems, fuel lines, and other components that require high strength and resistance to heat and corrosion. Their durability and reliability make them an essential component in modern vehicles, ensuring optimal performance and longevity.

In the agricultural sector, ASTM A106 Gr. B BS, DIN, GB, JIS St45 DN15 A333 A335 carbon steel pipes are commonly used for irrigation systems, water supply, and drainage. These pipes are known for their high flow capacity, durability, and resistance to corrosion, making them ideal for agricultural applications. Their ability to withstand harsh environmental conditions and heavy loads makes them a reliable choice for farmers and agricultural businesses.

Overall, ASTM A106 Gr. B BS, DIN, GB, JIS St45 DN15 A333 A335 carbon steel pipes are essential components in a wide range of industries due to their excellent properties and versatility. Whether it is in the oil and gas industry, construction industry, manufacturing industry, automotive industry, or agricultural sector, these pipes play a crucial role in ensuring the safe and efficient operation of various processes and applications. Their high strength, durability, and resistance to corrosion make them a preferred choice for engineers, designers, and manufacturers looking for reliable and cost-effective solutions for their projects.