Table of Contents

Blog Topic About Basalt Fiber for Industrial Reinforcement

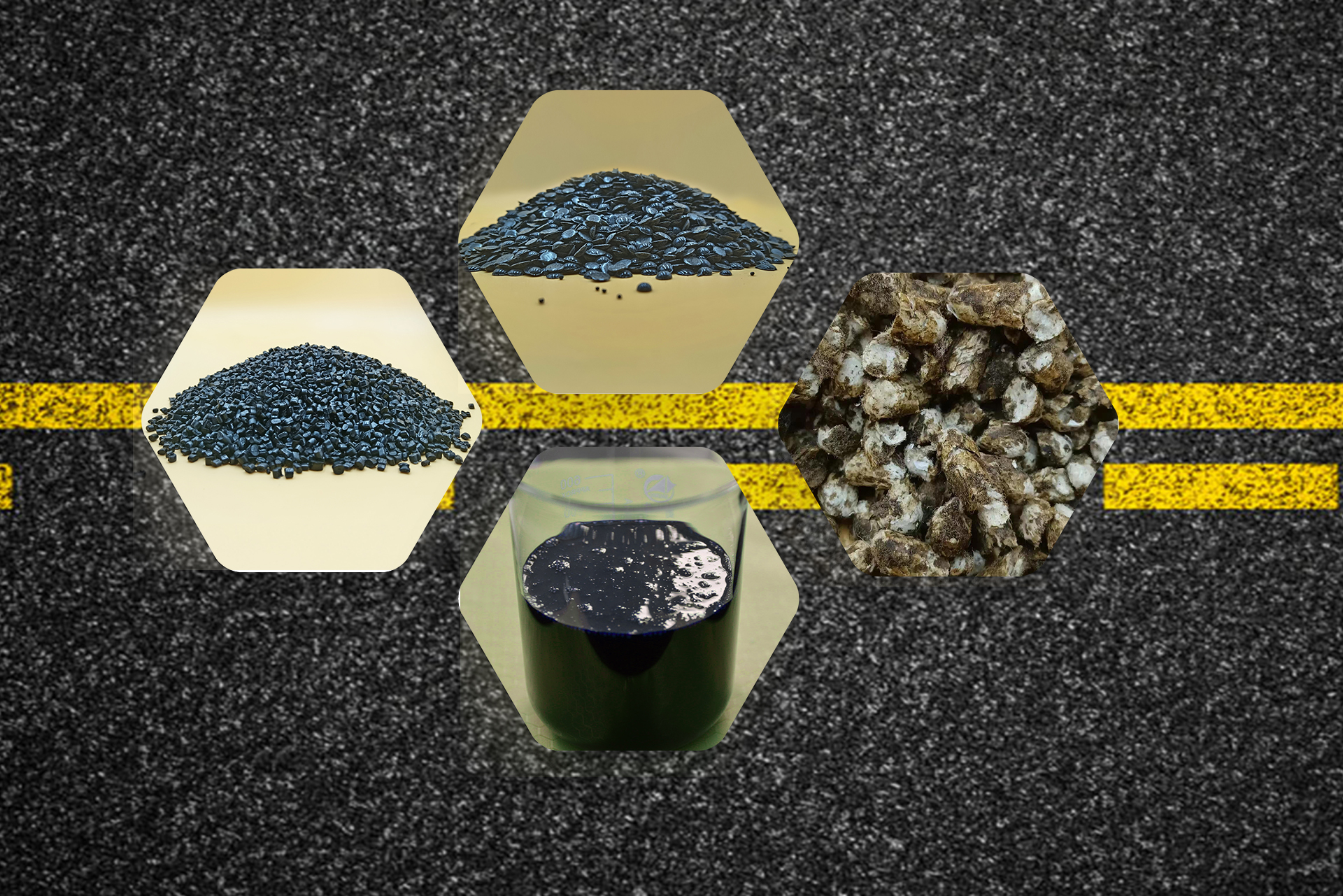

Basalt fiber is a versatile material that has gained popularity in various industries for its exceptional strength and durability. One of the key applications of basalt fiber is in industrial reinforcement, where it is used to enhance the performance and longevity of various products and structures. In this article, we will explore the use of basalt fiber for industrial reinforcement in plastics and road stabilization.

Basalt fiber reinforcement in plastics is a common practice in the manufacturing industry. By incorporating basalt fiber into plastic materials, manufacturers can significantly improve the mechanical properties of the final product. Basalt fiber has a high tensile strength and excellent resistance to Chemicals and temperature fluctuations, making it an ideal reinforcement material for plastics. The addition of basalt fiber can enhance the stiffness, impact resistance, and overall durability of plastic components, making them suitable for a wide range of applications.

| Serial Number | Products |

| 1 | Durable basalt fiber in pavement design |

In addition to plastics, basalt fiber is also used for reinforcement in road stabilization. Roads are subjected to heavy loads and harsh environmental conditions, which can Lead to deterioration and premature wear. By incorporating basalt fiber into road construction materials, engineers can improve the strength and durability of the road surface, reducing the need for frequent repairs and maintenance. Basalt fiber reinforcement can help prevent cracking, rutting, and other forms of damage, extending the lifespan of the road and ensuring a smoother and safer driving experience for motorists.

The use of basalt fiber for industrial reinforcement offers several advantages over traditional reinforcement materials. Basalt fiber is lightweight, yet incredibly strong, making it an ideal choice for applications where weight reduction is a priority. Additionally, basalt fiber is non-corrosive and non-conductive, making it suitable for use in environments where exposure to moisture, chemicals, or electrical currents is a concern. Basalt fiber is also eco-friendly, as it is made from natural volcanic rock and does not require the use of harmful chemicals or additives during production.

When it comes to incorporating basalt fiber into industrial applications, proper design and manufacturing techniques are essential to ensure optimal performance. Engineers and manufacturers must carefully consider factors such as fiber orientation, fiber content, and processing conditions to achieve the desired mechanical properties and durability. Testing and quality control measures are also crucial to verify the performance of basalt fiber-reinforced products and ensure compliance with industry standards and regulations.

In conclusion, basalt fiber is a valuable material for industrial reinforcement, offering superior strength, durability, and environmental benefits. Whether used in plastics, road stabilization, or other applications, basalt fiber can help enhance the performance and longevity of products and structures. By leveraging the unique properties of basalt fiber, manufacturers and engineers can create innovative and sustainable solutions for a wide range of industrial challenges.