Table of Contents

Distribution Transformer: Key Components and Maintenance Tips

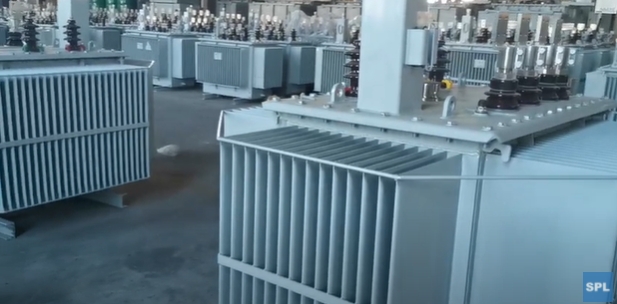

Distribution Transformers are a crucial component in the electrical grid, responsible for stepping Down the voltage from the medium voltage level to the low voltage level that is used in homes and businesses. These transformers play a vital role in ensuring a reliable supply of electricity to consumers, and their proper maintenance is essential to prevent power outages and ensure the Safety of the electrical system.

One of the key components of a distribution transformer is the core, which is typically made of laminated steel sheets to reduce eddy current losses. The core provides a path for the magnetic flux generated by the primary winding to induce a voltage in the secondary winding. The windings, which are made of Copper or Aluminum wire, are another critical component of the transformer. The primary winding is connected to the high voltage side of the electrical system, while the secondary winding is connected to the low voltage side.

In addition to the core and windings, distribution transformers also contain insulation materials to prevent electrical breakdown and ensure the safety of the transformer. The insulation materials are designed to withstand the high temperatures and electrical stresses that the transformer may experience during operation. Regular maintenance of the insulation is essential to prevent failures and extend the lifespan of the transformer.

To ensure the proper functioning of a distribution transformer, it is important to perform regular maintenance checks and inspections. One of the key maintenance tasks is to check the oil level and quality in the transformer. The oil serves as a coolant and insulating medium for the transformer, and its level should be maintained within the specified range. In addition, the oil should be tested regularly for signs of contamination or degradation, and replaced if necessary.

Another important maintenance task is to inspect the Bushings and connections of the transformer for signs of damage or corrosion. The bushings provide a connection point for the high voltage cables, and any damage to the bushings can Lead to electrical faults and failures. The connections should be tightened and inspected regularly to ensure proper electrical contact and prevent overheating.

| model | Rating\\u00a0power\\u00a0\\uff08KVA\\uff09 | Voltage\\u00a0combination\\uff08KV\\uff09 | Off-load\\u00a0losses\\uff08W\\uff09 | Load\\u00a0losses\\uff08W\\uff09 | Off-load\\u00a0current\\u00a0\\uff08%\\uff09 | Short-circuit\\u00a0voltage\\u00a0\\uff08%\\uff09 |

| SC13-30 | 30 | 6,6.3,6.6,10,11/0.4 | 150 | 710 | 2.3 | 4.0 |

| SC13-50 | 50 | 6,6.3,6.6,10,11/0.4 | 215 | 1000 | 2.2 | 4.0 |

| SC13-80 | 80 | 6,6.3,6.6,10,11/0.4 | 295 | 1380 | 1.7 | 4.0 |

| SC13-100 | 100 | 6,6.3,6.6,10,11/0.4 | 320 | 1570 | 1.7 | 4.0 |

| SC13-125 | 125 | 6,6.3,6.6,10,11/0.4 | 375 | 1850 | 1.5 | 4.0 |

| SCB13-160 | 160 | 6,6.3,6.6,10,11/0.4 | 430 | 2130 | 1.5 | 4.0 |

| SCB13-200 | 200 | 6,6.3,6.6,10,11/0.4 | 495 | 2530 | 1.3 | 4.0 |

| SCB13-250 | 250 | 6,6.3,6.6,10,11/0.4 | 575 | 2760 | 1.3 | 4.0 |

| SCB13-315 | 315 | 6,6.3,6.6,10,11/0.4 | 705 | 3470 | 1.1 | 4.0 |

| SCB13-400 | 400 | 6,6.3,6.6,10,11/0.4 | 785 | 3990 | 1.1 | 4.0 |

| SCB13-500 | 500 | 6,6.3,6.6,10,11/0.4 | 930 | 4880 | 1.1 | 4.0 |

| SCB13-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1070 | 5880 | 0.9 | 4.0 |

| SCB13-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1040 | 5960 | 0.9 | 6.0 |

| SCB13-800 | 800 | 6,6.3,6.6,10,11/0.4 | 1210 | 6960 | 0.9 | 6.0 |

| SCB13-1000 | 1000 | 6,6.3,6.6,10,11/0.4 | 1410 | 8130 | 0.9 | 6.0 |

| SCB13-1250 | 1250 | 6,6.3,6.6,10,11/0.4 | 1670 | 9690 | 0.9 | 6.0 |

| SCB13-1600 | 1600 | 6,6.3,6.6,10,11/0.4 | 1960 | 11700 | 0.9 | 6.0 |

| SCB13-2000 | 2000 | 6,6.3,6.6,10,11/0.4 | 2440 | 14400 | 0.7 | 6.0 |

| SCB13-2500 | 2500 | 6,6.3,6.6,10,11/0.4 | 2880 | 17100 | 0.7 | 6.0 |

| Type | Rating\\u00a0capacity\\u00a0\\uff08KVA\\uff09 | Voltage\\u00a0combination\\uff08KV\\uff09 | Off-load\\u00a0losses\\uff08W\\uff09 | Load\\u00a0losses\\uff08W\\uff09 | Off-load\\u00a0current\\u00a0\\uff08%\\uff09 | Short-circuit\\u00a0voltage\\u00a0\\uff08%\\uff09 |

| SCH15-30 | 30 | 6,6.3,6.6,10,11/0.4 | 70 | 710 | 1.6 | 4.0 |

| SCH15-50 | 50 | 6,6.3,6.6,10,11/0.4 | 90 | 1000 | 1.4 | 4.0 |

| SCH15-80 | 80 | 6,6.3,6.6,10,11/0.4 | 120 | 1380 | 1.3 | 4.0 |

| SCH15-100 | 100 | 6,6.3,6.6,10,11/0.4 | 130 | 1570 | 1.2 | 4.0 |

| SCH15-125 | 125 | 6,6.3,6.6,10,11/0.4 | 150 | 1850 | 1.1 | 4.0 |

| SC(B)H15-160 | 160 | 6,6.3,6.6,10,11/0.4 | 170 | 2130 | 1.1 | 4.0 |

| SC(B)H15-200 | 200 | 6,6.3,6.6,10,11/0.4 | 200 | 2530 | 1.0 | 4.0 |

| SC(B)H15-250 | 250 | 6,6.3,6.6,10,11/0.4 | 230 | 2760 | 1.0 | 4.0 |

| SC(B)H15-315 | 315 | 6,6.3,6.6,10,11/0.4 | 280 | 3470 | 0.9 | 4.0 |

| SC(B)H15-400 | 400 | 6,6.3,6.6,10,11/0.4 | 310 | 3990 | 0.8 | 4.0 |

| SC(B)H15-500 | 500 | 6,6.3,6.6,10,11/0.4 | 360 | 4880 | 0.8 | 4.0 |

| SC(B)H15-630 | 630 | 6,6.3,6.6,10,11/0.4 | 420 | 5880 | 0.7 | 4.0 |

| SC(B)H15-630 | 630 | 6,6.3,6.6,10,11/0.4 | 410 | 5960 | 0.7 | 6.0 |

| SC(B)H15-800 | 800 | 6,6.3,6.6,10,11/0.4 | 480 | 6960 | 0.7 | 6.0 |

| SC(B)H15-1000 | 1000 | 6,6.3,6.6,10,11/0.4 | 550 | 8130 | 0.6 | 6.0 |

| SC(B)H15-1250 | 1250 | 6,6.3,6.6,10,11/0.4 | 650 | 9690 | 0.6 | 6.0 |

| SC(B)H15-1600 | 1600 | 6,6.3,6.6,10,11/0.4 | 780 | 11730 | 0.6 | 6.0 |

| SC(B)H15-2000 | 2000 | 6,6.3,6.6,10,11/0.4 | 1000 | 14450 | 0.5 | 6.0 |

| SC(B)H15-2500 | 2500 | 6,6.3,6.6,10,11/0.4 | 1200 | 17170 | 0.5 | 6.0 |

Regular testing of the transformer’s insulation resistance is also essential to detect any signs of deterioration or breakdown. Insulation resistance testing should be performed at regular intervals using a megohmmeter, and any abnormalities should be investigated and addressed promptly. In addition, the transformer should be inspected for signs of overheating, such as discolored insulation or hot spots on the tank.

In conclusion, distribution transformers are a critical component of the electrical grid, and their proper maintenance is essential to ensure a reliable supply of electricity to consumers. By understanding the key components of a distribution transformer and following the maintenance tips outlined in this article, you can help prevent power outages and ensure the safety and reliability of the electrical system. Remember to consult with a specialist or watch informative videos to learn more about distribution transformer maintenance and best practices.