Table of Contents

Avantages de l’utilisation de tuyaux SMLS ronds ASTM A106, tuyaux en acier sans soudure pour conduites de pétrole et de gaz

Un autre avantage du tuyau rond en acier sans soudure ASTM A106 SMLS Pipe est sa durabilité. Ce type de tuyau est conçu pour durer de nombreuses années, même dans des conditions environnementales difficiles. Sa résistance à la corrosion et à la rouille signifie qu’il peut résister à l’exposition à l’humidité, aux produits chimiques et à d’autres substances corrosives que l’on trouve couramment dans les installations de production pétrolière et gazière. Cette durabilité permet de minimiser le besoin d’entretien et de réparations fréquents, ce qui permet d’économiser du temps et de l’argent à long terme.

En plus de sa résistance et de sa durabilité, le tuyau rond SMLS en acier sans soudure ASTM A106 offre d’excellentes performances en termes d’efficacité d’écoulement. La surface intérieure lisse de ce tuyau permet un flux efficace et ininterrompu de pétrole et de gaz, réduisant ainsi la friction et la chute de pression le long du pipeline. Cela se traduit par une amélioration de l’efficacité énergétique et une réduction des coûts d’exploitation pour les sociétés pétrolières et gazières.

Principales caractéristiques et spécifications du tuyau rond SMLS en acier sans soudure ASTM A106

Applications et industries utilisant des tuyaux ronds SMLS Tuyaux en acier sans soudure ASTM A106

Une autre industrie qui s’appuie sur les tuyaux ronds SMLS en acier sans soudure ASTM A106 est l’industrie pétrochimique. Les usines pétrochimiques utilisent ce type de canalisations pour transporter divers produits chimiques et gaz au sein de l’installation. Les propriétés de résistance à la corrosion de l’acier ASTM A106 en font un choix idéal pour la manipulation de substances corrosives, garantissant l’intégrité du système de tuyauterie dans le temps. De plus, la conception sans soudure du tuyau minimise le risque de fuites et de contamination, ce qui en fait une option fiable pour les applications pétrochimiques.

En plus des industries pétrolière, gazière et pétrochimique, le tuyau rond en acier sans soudure ASTM A106 pour tuyaux SMLS est également utilisé dans le secteur de la construction. Ce type de canalisation est couramment utilisé dans la construction d’immeubles de grande hauteur, de ponts et d’autres structures nécessitant un système de canalisation fiable et durable. La haute résistance et la résistance à la corrosion de l’acier ASTM A106 le rendent adapté aux applications structurelles, garantissant la sécurité et la longévité du bâtiment.

De plus, les tuyaux ronds SMLS en acier sans soudure ASTM A106 sont utilisés dans l’industrie manufacturière pour diverses applications. Les fabricants utilisent ce type de canalisations pour acheminer des fluides, des gaz et d’autres matériaux au sein de leurs installations. La conception sans couture du tuyau assure un flux fluide des matériaux, réduisant ainsi le risque de blocages et de temps d’arrêt. De plus, la haute résistance de l’acier ASTM A106 le rend adapté à la manipulation d’applications lourdes, garantissant l’efficacité et la fiabilité du processus de fabrication.

Dans l’ensemble, les tuyaux ronds SMLS en acier sans soudure ASTM A106 sont une option polyvalente et fiable pour une large gamme de produits. gamme d’applications et d’industries. Sa haute résistance, sa durabilité et sa résistance à la corrosion en font un choix idéal pour le transport de pétrole et de gaz, la manipulation de produits chimiques et de gaz, la construction de bâtiments et la fabrication de divers produits. Que vous soyez dans l’industrie pétrolière et gazière, l’industrie pétrochimique, l’industrie de la construction ou l’industrie manufacturière, les tuyaux en acier sans soudure ronds SMLS ASTM A106 sont un atout précieux qui peut répondre à vos besoins en matière de tuyauterie de manière efficace et efficiente.

Key Features and Specifications of Round SMLS Pipe ASTM A106 Seamless Steel Pipe

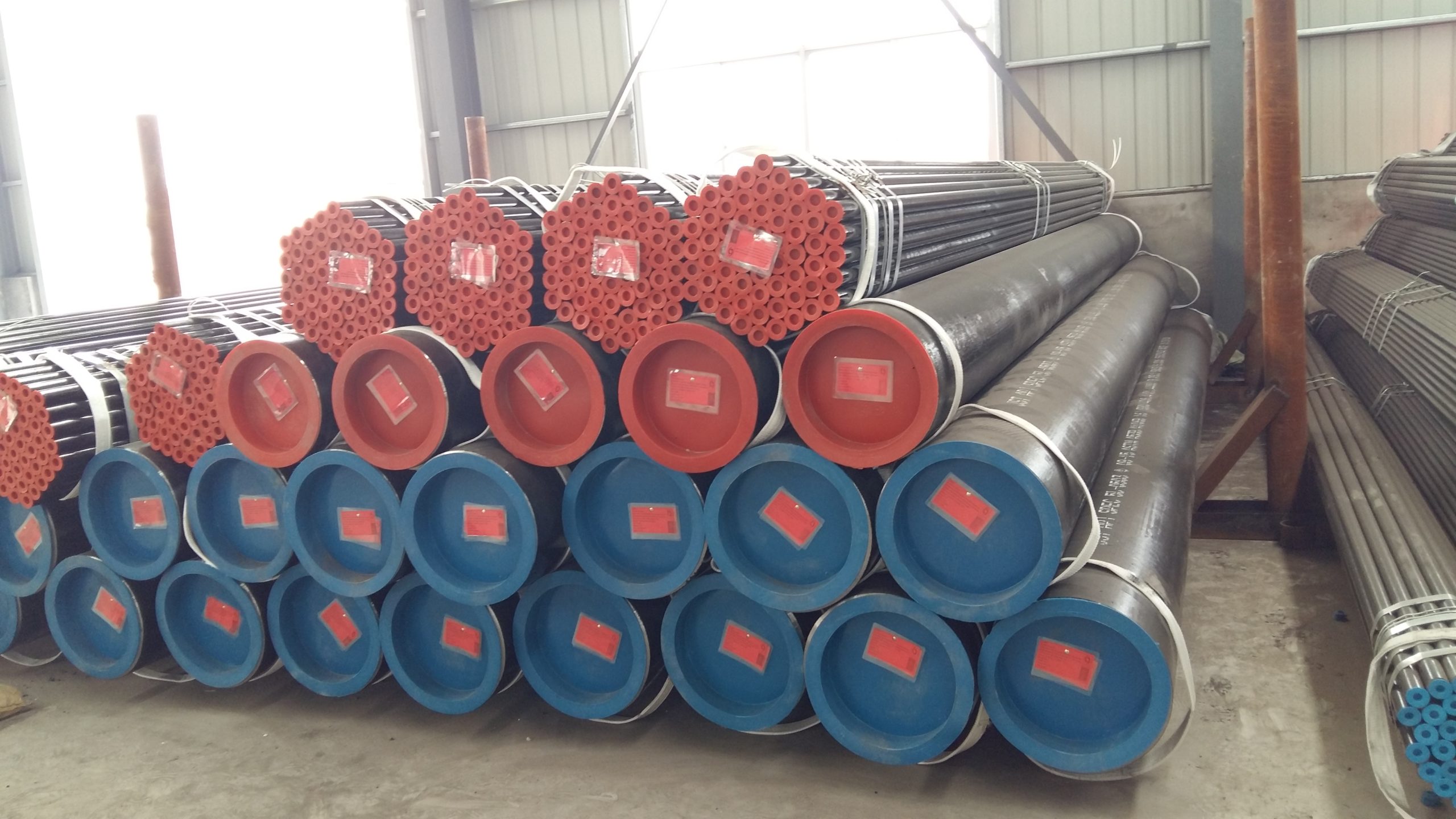

Round SMLS Pipe ASTM A106 Seamless Steel Pipe is a popular choice for oil and gas line applications due to its high strength, durability, and corrosion resistance. This seamless pipe is manufactured using a process that involves heating a solid steel billet and then forcing it through a die to create a cylindrical shape. The resulting pipe has a smooth interior surface, which allows for efficient flow of liquids and gases.

One of the key features of Round SMLS Pipe ASTM A106 Seamless Steel Pipe is its high tensile strength. This pipe is able to withstand high pressure and temperature conditions, making it ideal for use in oil and gas pipelines. Additionally, the seamless construction of this pipe eliminates the risk of weak points or leaks that can occur with welded pipes.

In terms of specifications, Round SMLS Pipe ASTM A106 Seamless Steel Pipe is available in a variety of sizes and wall thicknesses to meet the specific requirements of different applications. The pipe is typically produced in lengths of 21 feet, but custom lengths can also be ordered to suit the needs of a particular project. This flexibility in sizing makes it easy to integrate this pipe into existing pipeline systems or to create new pipelines from scratch.

Another important specification to consider when choosing Round SMLS Pipe ASTM A106 Seamless Steel Pipe is the material grade. This pipe is typically made from Carbon Steel, which offers excellent mechanical properties and is well-suited for use in demanding environments. The ASTM A106 specification sets the standards for the chemical composition and mechanical properties of the steel used in this pipe, ensuring that it meets the necessary requirements for strength and durability.

In addition to its high strength and durability, Round SMLS Pipe ASTM A106 Seamless Steel Pipe also offers excellent corrosion resistance. This pipe is designed to withstand exposure to harsh Chemicals, moisture, and other corrosive elements commonly found in oil and gas production environments. The seamless construction of this pipe helps to prevent the formation of rust and corrosion, ensuring a long service life and minimal maintenance requirements.

When it comes to installation, Round SMLS Pipe ASTM A106 Seamless Steel Pipe is relatively easy to work with. The seamless construction of this pipe eliminates the need for welding, which can be a time-consuming and costly process. Instead, this pipe can be easily cut to size and connected using standard Pipe Fittings, making it a convenient and cost-effective option for oil and gas line installations.

In conclusion, Round SMLS Pipe ASTM A106 Seamless Steel Pipe is a reliable and versatile choice for oil and gas line applications. With its high strength, durability, and corrosion resistance, this pipe is well-suited for use in demanding environments where reliable performance is essential. By considering the key features and specifications of this pipe, engineers and project managers can confidently select Round SMLS Pipe ASTM A106 Seamless Steel Pipe for their next oil and gas pipeline project.

Applications and Industries that Utilize Round SMLS Pipe ASTM A106 Seamless Steel Pipe

Round SMLS Pipe ASTM A106 Seamless Steel Pipe is a popular choice for various applications in the oil and gas industry. This type of pipe is known for its high strength, durability, and resistance to corrosion, making it ideal for Transporting oil and gas in harsh environments. In this article, we will explore the different applications and industries that utilize Round SMLS Pipe ASTM A106 Seamless Steel Pipe.

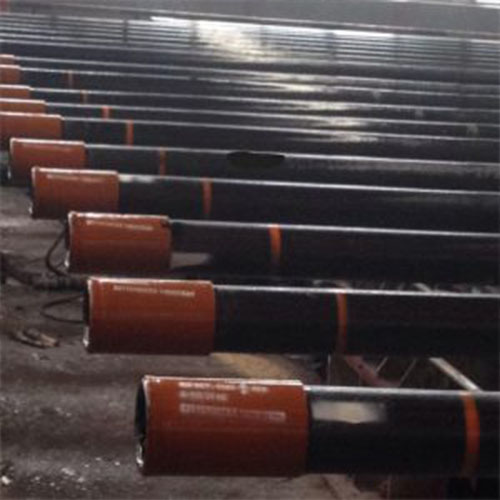

One of the primary applications of Round SMLS Pipe ASTM A106 Seamless Steel Pipe is in the transportation of oil and gas. This type of pipe is commonly used in pipelines that carry oil and gas from production sites to refineries and distribution centers. The seamless design of the pipe ensures a smooth flow of oil and gas, reducing the risk of leaks and spills. Additionally, the high strength of ASTM A106 steel makes it suitable for high-pressure applications, ensuring the safe and efficient transport of oil and gas.

Another industry that relies on Round SMLS Pipe ASTM A106 Seamless Steel Pipe is the petrochemical industry. Petrochemical plants use this type of pipe to transport various chemicals and gases within the facility. The corrosion-resistant properties of ASTM A106 steel make it an ideal choice for handling corrosive substances, ensuring the integrity of the piping system over time. Additionally, the seamless design of the pipe minimizes the risk of leaks and contamination, making it a reliable option for petrochemical applications.

In addition to the oil and gas and petrochemical industries, Round SMLS Pipe ASTM A106 Seamless Steel Pipe is also used in the construction industry. This type of pipe is commonly used in the construction of high-rise buildings, bridges, and other structures that require a reliable and durable piping system. The high strength and corrosion resistance of ASTM A106 steel make it suitable for structural applications, ensuring the Safety and longevity of the building.

Furthermore, Round SMLS Pipe ASTM A106 Seamless Steel Pipe is utilized in the manufacturing industry for various applications. Manufacturers use this type of pipe for conveying fluids, gases, and other materials within their facilities. The seamless design of the pipe ensures a smooth flow of materials, reducing the risk of blockages and downtime. Additionally, the high strength of ASTM A106 steel makes it suitable for handling heavy-duty applications, ensuring the efficiency and reliability of the manufacturing process.

Overall, Round SMLS Pipe ASTM A106 Seamless Steel Pipe is a versatile and reliable option for a wide range of applications and industries. Its high strength, durability, and corrosion resistance make it an ideal choice for transporting oil and gas, handling chemicals and gases, constructing buildings, and manufacturing various products. Whether you are in the oil and gas industry, petrochemical industry, construction industry, or manufacturing industry, Round SMLS Pipe ASTM A106 Seamless Steel Pipe is a valuable asset that can meet your piping needs effectively and efficiently.