Table of Contents

The Importance of Road Security: Preventing Rutting

Road security is a critical aspect of transportation infrastructure that ensures the Safety of motorists and pedestrians alike. One common issue that can compromise road security is rutting, which refers to the formation of depressions or grooves in the road surface caused by repeated traffic loading. Rutting can Lead to reduced skid resistance, increased vehicle wear and tear, and ultimately, a higher risk of accidents. To address this issue, road authorities and engineers have developed rutting prevention agents, such as rutting inhibitor additives, that can help mitigate the effects of rutting and prolong the lifespan of roads.

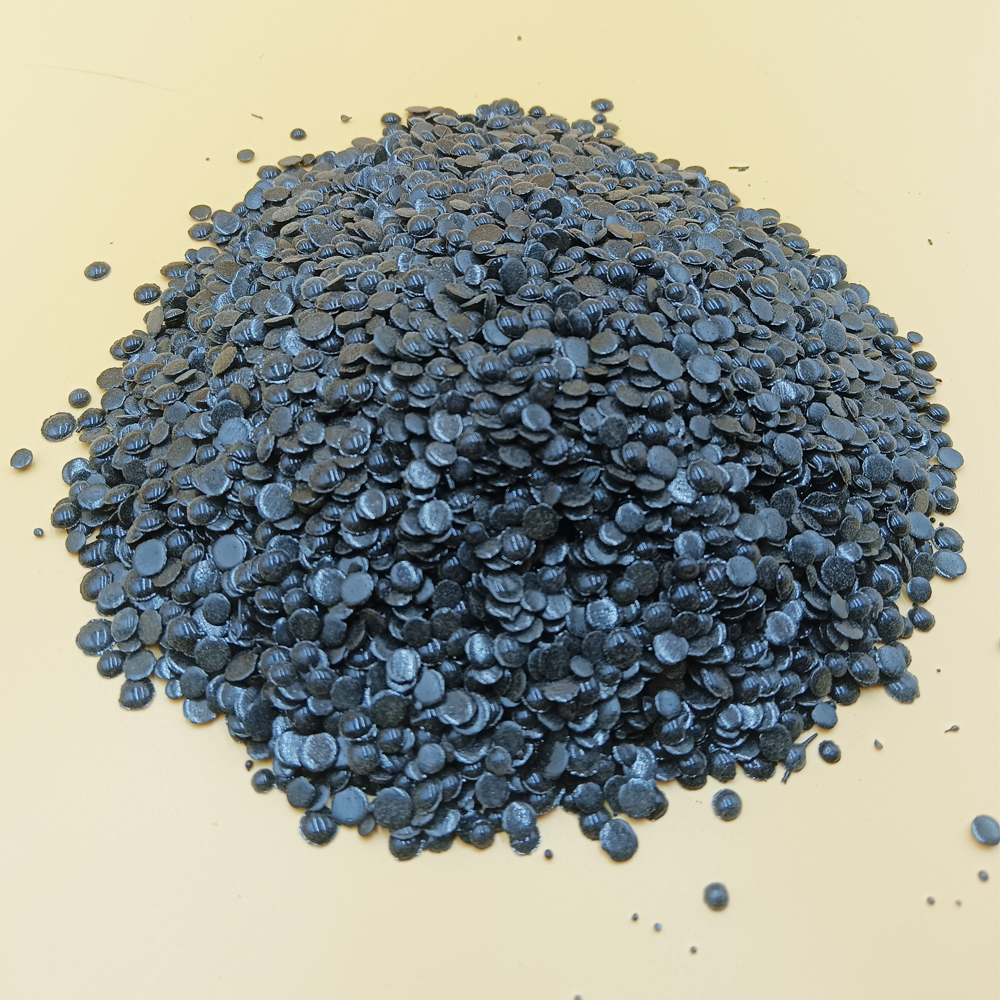

Rutting inhibitor additives are chemical compounds that are mixed with asphalt during the pavement construction process to improve the resistance of the road surface to rutting. These additives work by modifying the properties of the asphalt binder, making it more resistant to deformation under heavy traffic loads. By incorporating rutting inhibitor additives into the asphalt mix, engineers can enhance the durability and performance of the road, ultimately reducing maintenance costs and improving road safety.

One of the key benefits of rutting inhibitor additives is their ability to increase the stiffness of the asphalt binder, which helps to distribute traffic loads more evenly across the road surface. This reduces the likelihood of rutting formation and minimizes the need for frequent repairs and maintenance. Additionally, rutting inhibitor additives can improve the fatigue resistance of the asphalt mix, allowing the road to withstand repeated loading without experiencing permanent deformation.

Incorporating rutting inhibitor additives into asphalt mixes is a cost-effective way to enhance the performance and longevity of roads. By preventing rutting formation, these additives can help to extend the service life of pavements, reducing the need for costly repairs and reconstruction projects. This not only saves money for road authorities and taxpayers but also minimizes disruptions to traffic flow and ensures the continued safety of road users.

Furthermore, rutting inhibitor additives can be customized to suit specific project requirements, allowing engineers to tailor the properties of the asphalt mix to the unique conditions of the road site. This flexibility enables road authorities to design pavements that are better suited to withstand the challenges of heavy traffic loads and adverse weather conditions, ultimately improving the overall resilience and reliability of the road network.

In conclusion, rutting inhibitor additives play a crucial role in preventing rutting and enhancing road security. By incorporating these additives into asphalt mixes, engineers can improve the durability, performance, and safety of roads, ultimately benefiting both road users and the wider community. As the demand for sustainable and resilient transportation infrastructure continues to grow, rutting inhibitor additives will undoubtedly play a key role in ensuring the long-term viability of our road networks.

Exploring the Effectiveness of Rutting Inhibitor Additives in Road Maintenance

Road maintenance is a crucial aspect of ensuring the safety and longevity of our transportation infrastructure. One common issue that road authorities face is rutting, which occurs when the surface of the road becomes uneven and develops depressions due to repeated traffic loading. Rutting not only affects the smoothness of the road surface but also poses a safety hazard to drivers. In order to prevent rutting and maintain the integrity of our roads, road authorities often turn to rutting inhibitor additives.

| Serial Number | Article Name |

| 1 | for highway modulus render |

Rutting inhibitor additives are materials that are mixed with asphalt to improve the resistance of the road surface to deformation. These additives work by enhancing the stiffness and durability of the asphalt, thereby reducing the likelihood of rutting. There are various types of rutting inhibitor additives available on the market, each with its own unique properties and benefits.

One of the most commonly used rutting inhibitor additives is Polymer-modified asphalt. This type of additive consists of polymers that are blended with the asphalt to improve its elasticity and resistance to deformation. Polymer-modified asphalt has been shown to significantly reduce rutting and increase the lifespan of the road surface. In addition, it also enhances the overall performance of the road, making it more durable and resistant to wear and tear.

Another type of rutting inhibitor additive is Fiber reinforcement. Fibers such as cellulose, polyester, and aramid are added to the asphalt mix to improve its tensile strength and resistance to rutting. Fiber reinforcement has been proven to be effective in preventing rutting and extending the life of the road surface. It also helps to reduce cracking and improve the overall performance of the road.

In recent years, nanotechnology has emerged as a promising solution for rutting prevention. Nanoparticles such as nanoclays, carbon nanotubes, and nanosilica are being used as rutting inhibitor additives to enhance the properties of asphalt. These nanoparticles have a high surface area and can improve the stiffness, durability, and resistance to deformation of the asphalt. They also help to reduce the temperature susceptibility of the asphalt, making it more suitable for use in various climatic conditions.

The effectiveness of rutting inhibitor additives in road maintenance has been demonstrated in numerous studies and field trials. Research has shown that roads treated with rutting inhibitor additives exhibit reduced rutting, improved smoothness, and increased durability compared to untreated roads. In addition, these additives have been found to be cost-effective in the long run, as they help to extend the life of the road surface and reduce the need for frequent repairs.

Overall, rutting inhibitor additives play a crucial role in maintaining the safety and integrity of our roads. By incorporating these additives into the asphalt mix, road authorities can effectively prevent rutting and ensure the long-term performance of the road surface. With advancements in technology and the development of new types of rutting inhibitor additives, the future looks promising for road maintenance and the prevention of rutting.