Table of Contents

The Strength and Durability of Wire Rope: A Comprehensive Guide

Wire rope, also known as steel wire rope cable, is a versatile and durable material that is used in a wide range of applications. From construction and mining to marine and transportation industries, wire rope plays a crucial role in providing strength and support for various tasks. But just how strong is wire rope, and what makes it such a reliable choice for heavy-duty applications?

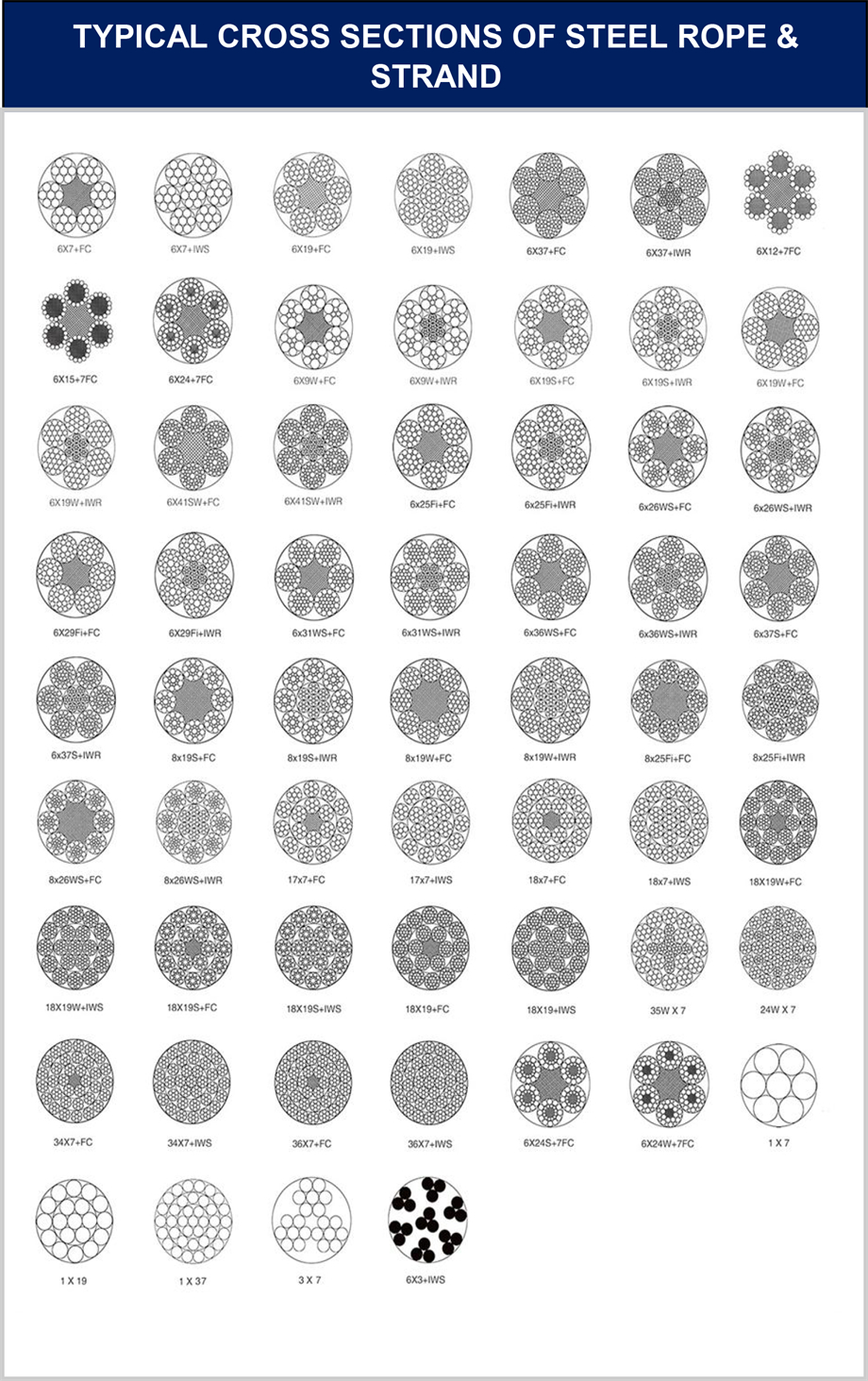

One of the key factors that determine the strength of wire rope is its construction. Wire rope is made up of multiple strands of steel wire twisted together to form a strong and flexible cable. The number of strands and the thickness of the individual wires can vary depending on the specific requirements of the application. Generally, the more strands and thicker wires a wire rope has, the stronger it will be.

In addition to its construction, the material used to make the steel wire also plays a significant role in determining the strength of the wire rope. High-quality steel with a high tensile strength is typically used to make wire rope, ensuring that it can withstand heavy loads and harsh conditions without breaking or stretching. The steel wires are often coated with a protective layer, such as galvanized Zinc, to enhance their durability and resistance to corrosion.

Another important factor that contributes to the strength of wire rope is its design. Wire rope can be manufactured in various configurations, including different types of cores and outer layers. A wire rope with a Fiber core, for example, will be more flexible and lightweight, while a wire rope with a steel core will be stronger and more resistant to crushing. The outer layer of the wire rope can also be customized to provide additional protection against abrasion, heat, or other environmental factors.

When it comes to testing the strength of wire rope, manufacturers use a variety of methods to ensure that it meets the required standards. Tensile testing is commonly used to determine the breaking strength of wire rope, while fatigue testing is used to assess its durability and resistance to repeated stress. These tests help to ensure that wire rope can safely support the loads it is designed for without failing prematurely.

In addition to its strength, wire rope is also known for its durability and longevity. When properly maintained and inspected regularly, wire rope can last for many years, even in harsh environments. Regular lubrication, cleaning, and inspection of wire rope can help to prevent corrosion, wear, and other issues that can affect its performance and lifespan.

In conclusion, wire rope is a strong and reliable material that is widely used in various industries for its durability and versatility. Its construction, material, design, and testing methods all contribute to its strength and performance, making it a popular choice for heavy-duty applications. Whether you are lifting heavy loads, securing cargo, or supporting structures, wire rope cable is a dependable and cost-effective solution that can withstand the toughest challenges.

Testing the Limits: How Much Weight Can a Steel Wire Rope Cable Really Hold?

Wire rope cables are a common sight in many industries, from construction to mining to transportation. These cables are used to lift heavy loads, support structures, and provide stability in a variety of applications. But just how strong are these steel wire ropes, and how much weight can they really hold?

To answer these questions, it is important to understand the construction of wire rope cables. These cables are made up of multiple strands of steel wire twisted together to form a strong and flexible rope. The number of strands and the thickness of the wire can vary depending on the intended use of the cable. The more strands and thicker the wire, the stronger the cable will be.

In order to determine the weight capacity of a steel wire rope cable, it must undergo rigorous testing. One common test is the breaking strength test, where a sample of the cable is subjected to increasing amounts of weight until it breaks. This test helps to determine the maximum load that the cable can safely support without failing.

Another important factor to consider when determining the weight capacity of a steel wire rope cable is the design factor. This factor takes into account various Safety factors, such as the type of load being lifted, the angle of the load, and the condition of the cable. By applying a design factor to the breaking strength of the cable, engineers can calculate a safe working load limit for the cable.

It is also important to consider the condition of the cable when determining its weight capacity. Over time, wire rope cables can become worn or damaged, which can weaken the cable and reduce its weight capacity. Regular inspections and maintenance are essential to ensure that the cable is in good condition and can safely support the intended load.

In addition to weight capacity, it is also important to consider the flexibility and durability of a steel wire rope cable. These cables are often subjected to harsh conditions, such as extreme temperatures, moisture, and heavy loads. A high-quality cable will be able to withstand these conditions and maintain its strength and flexibility over time.

Overall, steel wire rope cables are incredibly strong and versatile, capable of supporting heavy loads in a variety of applications. By understanding the construction of wire rope cables, conducting rigorous testing, and considering factors such as design and condition, engineers can determine the weight capacity of a cable and ensure that it is used safely and effectively.

In conclusion, steel wire rope cables are a vital component in many industries, providing strength, flexibility, and durability in a variety of applications. By understanding the factors that determine the weight capacity of a cable, engineers can ensure that it is used safely and effectively to support heavy loads. With proper testing, maintenance, and care, steel wire rope cables can continue to be a reliable and essential tool for lifting and supporting heavy loads.