Table of Contents

Benefits of Using ISO Approved Cooler Datang Heat Exchanger Finned Pipe Forced Oil Circulating Air Cooler

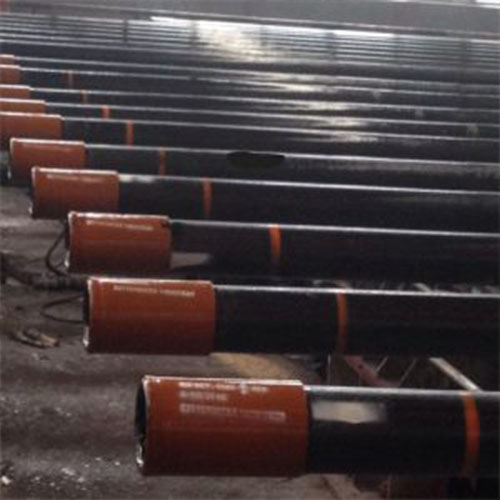

Cooling systems are essential in various industries to maintain optimal operating temperatures for equipment and machinery. One popular choice for cooling systems is the ISO approved Cooler Datang Heat Exchanger Finned Pipe Forced Oil Circulating Air Cooler. This innovative cooling solution offers a range of benefits that make it a preferred option for many businesses.

One of the key advantages of the Cooler Datang Heat Exchanger is its efficiency in dissipating heat. The finned pipe design maximizes the surface area for heat transfer, allowing for rapid cooling of the circulating oil. This efficient heat exchange process helps to prevent overheating and ensures the smooth operation of equipment.

In addition to its high heat dissipation capabilities, the Cooler Datang Heat Exchanger is also known for its durability and reliability. Constructed from high-quality materials and designed to withstand harsh operating conditions, this Cooling System is built to last. Its robust construction ensures long-term performance and minimal maintenance requirements, saving businesses time and money in the long run.

Another benefit of the Cooler Datang Heat Exchanger is its compact design. With a smaller footprint compared to traditional cooling systems, this air cooler can be easily integrated into existing equipment layouts without taking up valuable space. This space-saving feature is particularly advantageous for businesses with limited floor space or those looking to optimize their operational efficiency.

Furthermore, the Cooler Datang Heat Exchanger is designed for easy installation and maintenance. With user-friendly features and a simple setup process, businesses can quickly implement this cooling system into their operations without any hassle. Additionally, the low maintenance requirements of the Cooler Datang Heat Exchanger help to minimize downtime and ensure continuous operation.

The ISO approval of the Cooler Datang Heat Exchanger is another significant benefit for businesses looking for a reliable and high-quality cooling solution. ISO certification ensures that the product meets international standards for quality and performance, giving businesses peace of mind knowing that they are investing in a trusted and reputable cooling system.

Overall, the Cooler Datang Heat Exchanger Finned Pipe Forced Oil Circulating Air Cooler offers a range of benefits that make it a top choice for businesses in need of efficient and reliable cooling solutions. From its high heat dissipation capabilities and durability to its compact design and easy installation, this cooling system provides businesses with a cost-effective and efficient solution for maintaining optimal operating temperatures.

In conclusion, the Cooler Datang Heat Exchanger is a versatile and reliable cooling system that offers a range of benefits for businesses across various industries. With its efficient heat dissipation capabilities, durability, compact design, and easy installation, this ISO approved air cooler is a valuable investment for businesses looking to optimize their operational efficiency and ensure the smooth operation of their equipment.

How to Properly Maintain and Extend the Lifespan of ISO Approved Cooler Datang Heat Exchanger Finned Pipe Forced Oil Circulating Air Cooler

ISO Approved Cooler Datang Heat Exchanger Finned Pipe Forced Oil Circulating Air Cooler is a high-quality cooling system that is designed to efficiently dissipate heat from various industrial processes. Proper maintenance of this equipment is crucial to ensure its optimal performance and extend its lifespan. In this article, we will discuss some key maintenance tips that can help you keep your ISO Approved Cooler in top condition.

Regular cleaning is essential to prevent the buildup of dirt, dust, and other debris on the fins of the heat exchanger. Over time, these contaminants can restrict airflow and reduce the cooling efficiency of the system. To clean the fins, use a soft brush or compressed air to remove any accumulated debris. Be sure to clean both the interior and exterior surfaces of the fins to ensure maximum heat transfer.

In addition to cleaning the fins, it is important to check the condition of the fan Blades regularly. Inspect the blades for any signs of damage or wear, such as cracks or bent edges. If any damage is found, replace the fan blades immediately to prevent further issues with the cooling system. Properly functioning fan blades are essential for maintaining proper airflow through the heat exchanger.

Another important maintenance task is to check the oil level in the circulating pump regularly. The circulating pump is responsible for moving the oil through the system to facilitate heat transfer. Low oil Levels can Lead to overheating and premature wear of the pump components. Check the oil level according to the manufacturer’s recommendations and top up as needed with the appropriate type of oil.

Inspect the Seals and Gaskets on the cooler for any signs of wear or leaks. Damaged seals can allow oil to escape from the system, leading to a loss of cooling efficiency and potential damage to other components. Replace any worn or damaged seals promptly to prevent leaks and ensure the proper functioning of the cooler.

Regularly monitor the temperature and pressure Gauges on the cooler to ensure that the system is operating within the recommended parameters. High temperatures or pressures can indicate a problem with the cooling system that needs to be addressed promptly. If you notice any abnormal readings, shut Down the system immediately and investigate the cause of the issue.

Lastly, schedule routine maintenance checks with a qualified technician to inspect the overall condition of the ISO Approved Cooler. A professional inspection can help identify any potential issues before they escalate into major problems. During the maintenance check, the technician can also perform any necessary repairs or adjustments to keep the cooler running smoothly.

In conclusion, proper maintenance is essential for extending the lifespan of your ISO Approved Cooler Datang Heat Exchanger Finned Pipe Forced Oil Circulating Air Cooler. By following these maintenance tips and scheduling regular inspections, you can ensure that your cooling system operates efficiently and reliably for years to come. Remember, a well-maintained cooler not only saves you money on repairs but also helps to prevent costly downtime in your industrial processes.