Table of Contents

Benefits of Using Basalt Fiber Yarn in High-Stress Applications

Basalt fiber yarn is a versatile material that has gained popularity in recent years for its exceptional strength and durability. It is made from natural basalt rock, which is melted Down and then extruded into fibers. These fibers are then spun into yarn, which can be used in a variety of high-stress applications.

One of the key benefits of using basalt fiber yarn in high-stress applications is its incredible strength-to-weight ratio. Basalt fibers are stronger than steel, yet much lighter, making them an ideal choice for applications where weight is a concern. This makes basalt fiber yarn particularly well-suited for use in aerospace, automotive, and sporting goods industries, where lightweight materials are essential.

| Number | Item |

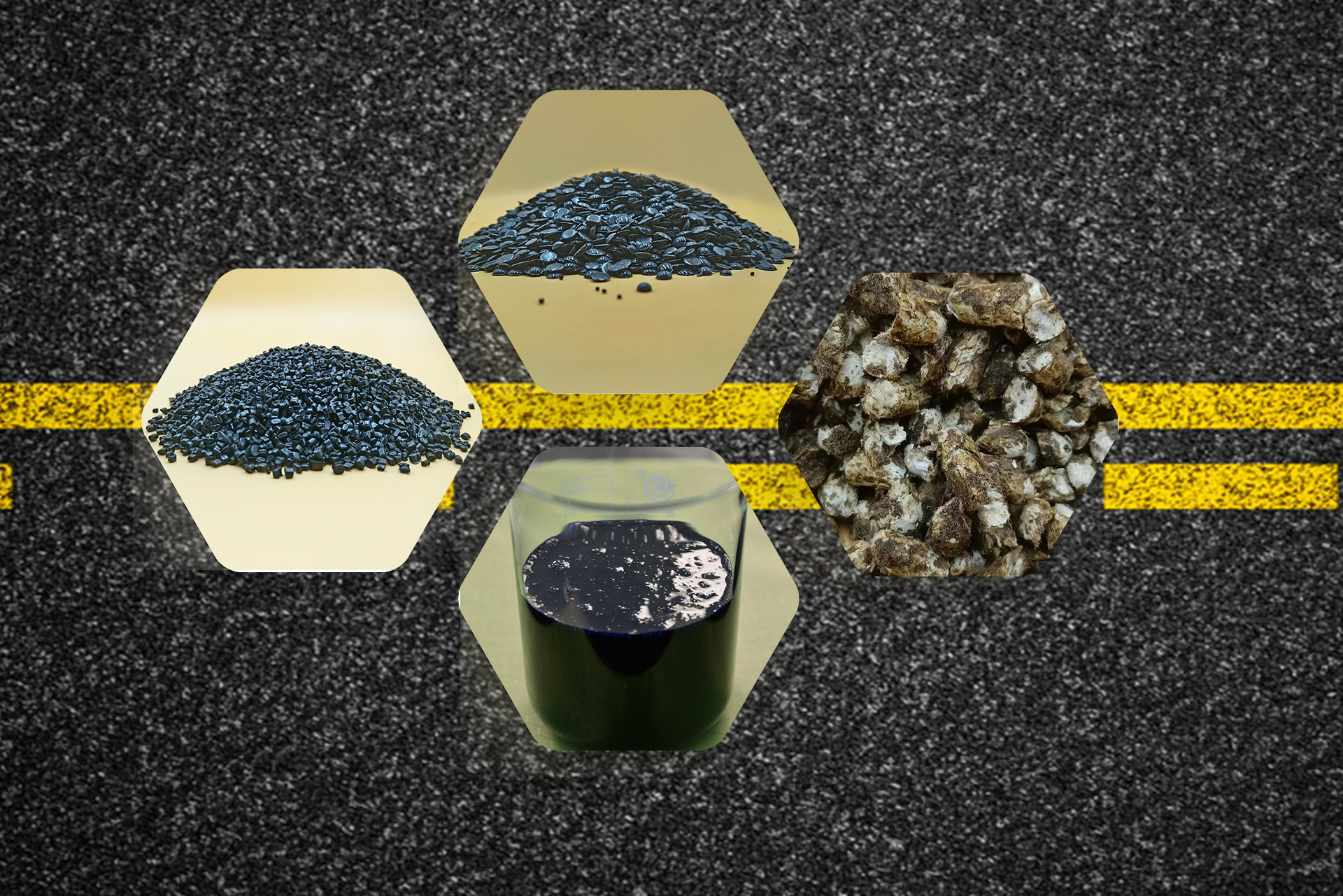

| 1 | Basalt fiber filler strands |

In addition to its strength, basalt fiber yarn also has excellent resistance to high temperatures. Basalt fibers have a high melting point, making them ideal for use in applications where exposure to extreme heat is a concern. This makes basalt fiber yarn a popular choice for use in fire protection systems, as well as in the construction of high-temperature furnaces and ovens.

Another benefit of using basalt fiber yarn in high-stress applications is its resistance to corrosion. Basalt fibers are not affected by moisture or Chemicals, making them an ideal choice for use in marine environments or in applications where exposure to corrosive substances is a concern. This makes basalt fiber yarn a popular choice for use in the construction of boats, bridges, and other structures that are exposed to harsh environmental conditions.

Furthermore, basalt fiber yarn is also highly flexible, making it easy to work with and mold into complex shapes. This flexibility makes basalt fiber yarn a popular choice for use in applications where intricate designs are required, such as in the construction of architectural facades or in the production of high-performance sporting goods.

In addition to its strength, durability, and flexibility, basalt fiber yarn is also an environmentally friendly choice. Basalt fibers are made from natural basalt rock, which is a renewable resource. This makes basalt fiber yarn a sustainable alternative to traditional materials such as steel or carbon fiber, which are often derived from non-renewable sources.

Overall, basalt fiber yarn offers a wide range of benefits for use in high-stress applications. Its exceptional strength-to-weight ratio, resistance to high temperatures and corrosion, flexibility, and environmental sustainability make it an ideal choice for a variety of industries. Whether used in aerospace, automotive, marine, or construction applications, basalt fiber yarn is a versatile material that is sure to meet the demands of even the most challenging projects.

How to Choose the Right Basalt Fiber Yarn for Your High-Stress Project

Basalt fiber yarn is a versatile material that is gaining popularity in high-stress applications due to its exceptional strength and durability. When choosing the right basalt fiber yarn for your project, there are several factors to consider to ensure optimal performance and longevity.

One of the most important considerations when selecting basalt fiber yarn is the diameter of the yarn. Thicker yarns typically offer higher tensile strength and are better suited for applications that require maximum durability and resistance to stress. However, thicker yarns may also be less flexible and more challenging to work with, so it is essential to strike a balance between strength and flexibility based on the specific requirements of your project.

In addition to diameter, the weave pattern of the basalt fiber yarn is another crucial factor to consider. Different weave patterns, such as plain weave, twill weave, and satin weave, offer varying Levels of strength, flexibility, and abrasion resistance. For high-stress applications that require maximum strength and durability, a tight weave pattern such as satin weave may be the most suitable choice. However, for applications that require more flexibility, a looser weave pattern such as plain weave may be more appropriate.

Another important consideration when choosing basalt fiber yarn is the surface treatment applied to the yarn. Surface treatments can enhance the adhesion between the yarn and the matrix material, improve the yarn’s resistance to abrasion and chemical exposure, and increase the overall performance of the composite material. Common surface treatments for basalt fiber yarn include sizing, silane coupling agents, and plasma treatment. It is essential to select a surface treatment that is compatible with the matrix material and the specific requirements of your project to ensure optimal performance.

When selecting basalt fiber yarn for high-stress applications, it is also essential to consider the environmental conditions in which the material will be used. Basalt fiber yarn is known for its excellent resistance to high temperatures, moisture, and chemicals, making it suitable for a wide range of harsh environments. However, it is essential to choose a yarn that is specifically designed to withstand the specific environmental conditions of your project to ensure long-term performance and durability.

In addition to the physical properties of the basalt fiber yarn, it is also crucial to consider the supplier’s reputation and track record. Working with a reputable supplier that has a proven track record of delivering high-quality basalt fiber yarns can help ensure the success of your project and minimize the risk of material defects or performance issues. It is essential to conduct thorough research and due diligence when selecting a supplier to ensure that you are getting the best possible product for your high-stress application.

In conclusion, basalt fiber yarn is an excellent choice for high-stress applications due to its exceptional strength, durability, and resistance to harsh environmental conditions. When choosing the right basalt fiber yarn for your project, it is essential to consider factors such as yarn diameter, weave pattern, surface treatment, environmental conditions, and supplier reputation to ensure optimal performance and longevity. By carefully evaluating these factors and selecting a high-quality basalt fiber yarn that meets your project’s specific requirements, you can create a durable and reliable composite material that will withstand the most demanding applications.