Table of Contents

The Process of Manufacturing Brake Pads in Japan

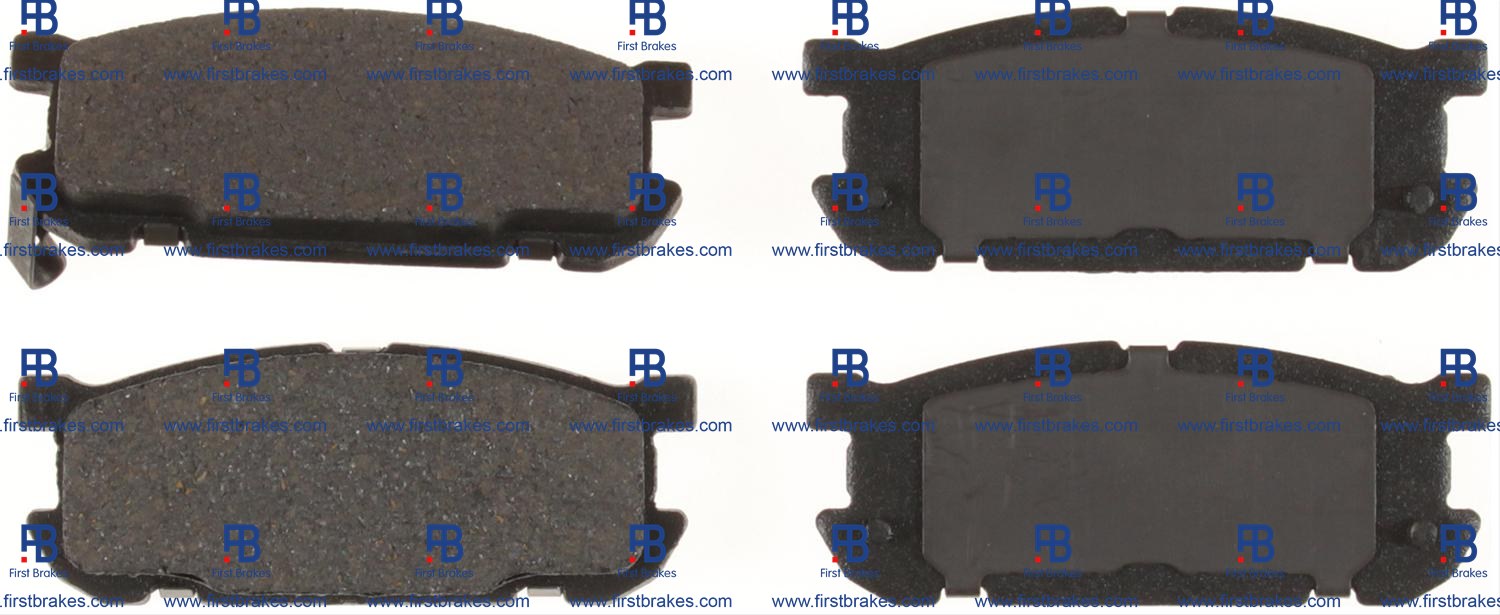

Japan is known for its high-quality manufacturing processes, and the production of brake pads is no exception. One crucial component of brake pads is the backing plate, which provides structural support and stability to the Pad. In Japan, there are specialized factories that focus solely on the production of backing plates for brake pads.

The process of manufacturing backing plates in Japan begins with the selection of raw materials. High-quality steel is typically used to ensure the durability and performance of the backing plate. The steel is carefully inspected for any defects or impurities before being processed further.

Once the raw materials have been selected, they are cut into the desired shape and size using precision machinery. This step is crucial to ensure that the backing plates will fit perfectly within the brake pad assembly. The cutting process is closely monitored to maintain consistency and accuracy throughout production.

After the backing plates have been cut, they undergo a series of shaping and forming processes. This involves bending and molding the steel to create the necessary contours and dimensions of the backing plate. Specialized equipment is used to ensure that each backing plate meets the exact specifications required for optimal performance.

Once the shaping and forming processes are complete, the backing plates are subjected to heat treatment. This involves exposing the plates to high temperatures to strengthen the steel and improve its resistance to wear and heat. Heat treatment is a critical step in the manufacturing process, as it ensures that the backing plates will perform effectively under the extreme conditions of braking.

After heat treatment, the backing plates are coated with a protective layer to prevent corrosion and enhance durability. This coating is carefully applied to ensure even coverage and adhesion to the steel surface. The coating also provides a smooth surface for the brake pad to make contact with, reducing noise and vibration during braking.

Once the backing plates have been coated, they undergo a final inspection to ensure quality and consistency. Each plate is carefully examined for any defects or imperfections that could affect performance. Any plates that do not meet the strict standards set by the factory are rejected and recycled to maintain the highest level of quality control.

In conclusion, the process of manufacturing backing plates for brake pads in Japan is a meticulous and precise operation. From the selection of raw materials to the final inspection of finished products, every step is carefully monitored to ensure the highest quality and performance. Japan’s dedication to excellence in manufacturing is evident in the production of backing plates for brake pads, making them a trusted choice for drivers around the world.