Table of Contents

Benefits of Using Large Caliber Pipe Mechanical Fitting-up System

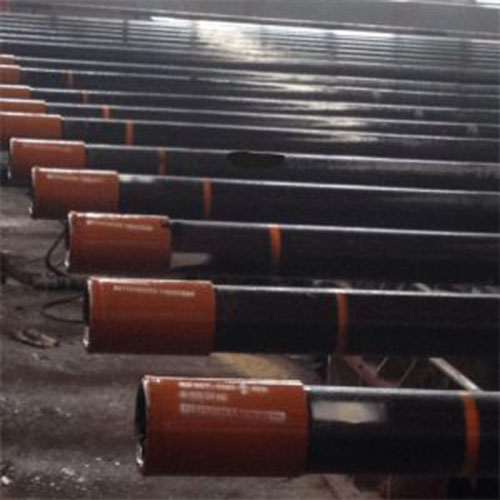

Large caliber pipes are essential components in various industries such as oil and gas, water treatment, and construction. These pipes are used to transport fluids, gases, and other materials over long distances. When it comes to assembling large caliber pipes, precision and accuracy are crucial to ensure the integrity and Safety of the pipeline. This is where the Large Caliber Pipe Mechanical Fitting-up System comes into play.

One of the key benefits of using the Large Caliber Pipe Mechanical Fitting-up System is its ability to streamline the fitting-up process. Traditional methods of fitting up large caliber pipes involve manual labor, which can be time-consuming and labor-intensive. With the Mechanical Fitting-up System, the process is automated, saving time and reducing the risk of human error. This results in faster and more efficient pipe assembly, ultimately leading to cost savings for the project.

Another advantage of the Mechanical Fitting-up System is its precision and accuracy. The system is designed to ensure that pipes are aligned correctly and securely connected, minimizing the risk of leaks or other issues Down the line. This level of precision is crucial in industries where even the smallest error can have serious consequences. By using the Mechanical Fitting-up System, companies can have peace of mind knowing that their pipelines are assembled with the highest level of accuracy.

In addition to efficiency and accuracy, the Mechanical Fitting-up System also offers versatility. The system is designed to accommodate a wide range of pipe sizes and materials, making it suitable for a variety of projects. Whether you are working with steel, PVC, or other materials, the Mechanical Fitting-up System can handle the job. This versatility makes it a valuable tool for companies that work on a diverse range of projects.

Furthermore, the Mechanical Fitting-up System is designed with safety in mind. By automating the fitting-up process, the system reduces the need for manual labor, which can be hazardous in certain environments. This not only protects workers from potential injuries but also ensures that the pipeline is assembled in a safe and secure manner. Safety is a top priority in any industry, and the Mechanical Fitting-up System helps companies meet their safety standards.

Overall, the Large Caliber Pipe Mechanical Fitting-up System offers a range of benefits for companies working with large caliber pipes. From increased efficiency and accuracy to versatility and safety, the system is a valuable tool for streamlining the fitting-up process. By investing in this technology, companies can save time and money while ensuring that their pipelines are assembled to the highest standards. Whether you are working on a small-scale project or a large industrial installation, the Mechanical Fitting-up System is a reliable and efficient solution for all your pipe fitting needs.

Tips for Efficiently Installing Large Caliber Pipe Mechanical Fitting-up System

Large caliber pipe mechanical fitting-up systems are essential components in various industries, including oil and gas, construction, and manufacturing. These systems are used to connect large diameter pipes efficiently and securely, ensuring the integrity of the overall structure. Proper installation of these systems is crucial to prevent leaks, reduce downtime, and ensure the safety of workers. In this article, we will discuss some tips for efficiently installing large caliber pipe mechanical fitting-up systems.

First and foremost, it is essential to carefully plan the installation process before starting. This includes determining the layout of the pipes, selecting the appropriate fittings, and ensuring that all necessary tools and equipment are readily available. By having a clear plan in place, you can streamline the installation process and avoid any unnecessary delays or complications.

When installing large caliber pipe mechanical fitting-up systems, it is crucial to pay attention to the alignment of the pipes. Proper alignment is essential to ensure a tight and secure fit, preventing leaks and other issues down the line. Use a level and measuring tape to ensure that the pipes are aligned correctly before securing them in place.

Another important tip for efficiently installing large caliber pipe mechanical fitting-up systems is to use the right tools and equipment. This includes pipe wrenches, pipe cutters, and other specialized tools designed for working with large diameter pipes. Using the right tools will not only make the installation process easier but also ensure that the fittings are installed correctly and securely.

In addition to using the right tools, it is also essential to follow the manufacturer’s instructions when installing large caliber pipe mechanical fitting-up systems. Each system is designed to work in a specific way, and deviating from the manufacturer’s guidelines can Lead to issues such as leaks, cracks, or other structural problems. Be sure to read and understand the installation instructions before starting the installation process.

Properly securing the fittings is another crucial aspect of efficiently installing large caliber pipe mechanical fitting-up systems. Use the appropriate Fasteners and ensure that they are tightened to the manufacturer’s specifications. This will help prevent the fittings from coming loose over time and ensure the integrity of the overall system.

Finally, it is essential to conduct thorough testing and inspection of the installed system before putting it into operation. This includes pressure testing the pipes to ensure that there are no leaks or other issues. Additionally, visually inspect the fittings and connections to ensure that everything is installed correctly and securely. By conducting thorough testing and inspection, you can identify and address any issues before they become more significant problems.

In conclusion, efficiently installing large caliber pipe mechanical fitting-up systems requires careful planning, proper alignment, the right tools and equipment, following manufacturer’s instructions, securing the fittings correctly, and conducting thorough testing and inspection. By following these tips, you can ensure that your installation is done correctly and securely, preventing leaks, reducing downtime, and ensuring the safety of workers. Proper installation of these systems is essential for the overall integrity and performance of the structure, so it is crucial to take the time and effort to do it right.