Table of Contents

Advantages of Using Spiral Welded Steel Tubes in Oil and Gas Industry

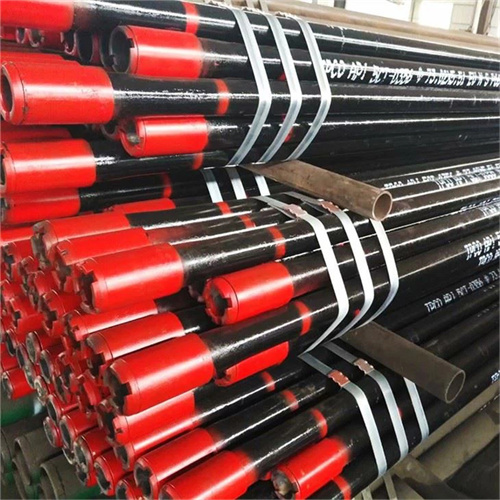

Spiral welded steel tubes have become a popular choice in the oil and gas industry due to their numerous advantages. These tubes are made by forming a continuous strip of steel into a spiral shape, which is then welded together along the seam. This manufacturing process results in a strong and durable tube that is well-suited for the demanding conditions of the oil and gas industry.

One of the key advantages of using spiral welded steel tubes in the oil and gas industry is their high strength-to-weight ratio. These tubes are able to withstand high pressure and temperature conditions, making them ideal for use in pipelines and other critical infrastructure. Additionally, the spiral welding process ensures that the tubes have a consistent wall thickness, which further enhances their strength and durability.

Another advantage of spiral welded steel tubes is their cost-effectiveness. These tubes are relatively easy to manufacture and can be produced in large quantities, which helps to keep costs Down. Additionally, the high strength-to-weight ratio of these tubes means that fewer materials are needed to achieve the same level of performance as traditional welded tubes, further reducing costs.

Spiral welded steel tubes are also highly resistant to corrosion, which is a critical factor in the oil and gas industry where exposure to harsh Chemicals and environmental conditions is common. The spiral welding process creates a smooth, continuous seam along the length of the tube, which helps to prevent corrosion from forming. Additionally, these tubes can be coated with protective coatings to further enhance their resistance to corrosion.

In addition to their strength, durability, and cost-effectiveness, spiral welded steel tubes also offer excellent flexibility and versatility. These tubes can be easily bent and shaped to fit a wide range of applications, making them ideal for use in complex pipeline systems. Additionally, the spiral welding process allows for the production of tubes in a variety of sizes and lengths, further increasing their versatility.

Overall, the advantages of using spiral welded steel tubes in the oil and gas industry are clear. These tubes offer a combination of strength, durability, cost-effectiveness, and versatility that make them an ideal choice for a wide range of applications. Whether used in pipelines, storage tanks, or other critical infrastructure, spiral welded steel tubes provide the performance and reliability that is essential in the demanding conditions of the oil and gas industry.