Table of Contents

Benefits of Using Oil Casing in the Oil Industry

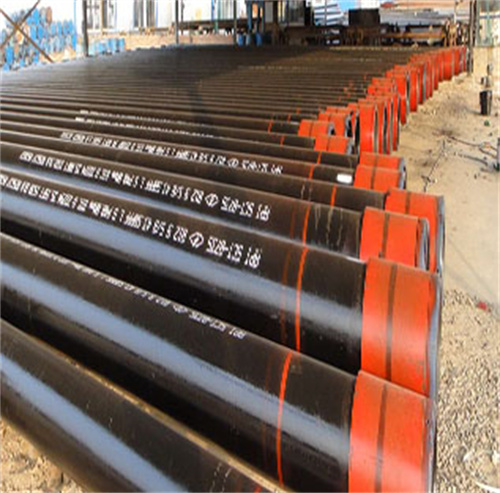

Oil casing plays a crucial role in the oil industry, providing structural support and protection for oil wells. This essential component helps to ensure the safe and efficient extraction of oil and gas from deep underground reservoirs. By using oil casing, companies can minimize the risk of well failure, reduce environmental impact, and improve overall operational efficiency.

One of the key benefits of using oil casing is its ability to prevent well collapse and maintain well integrity. Oil wells are subject to high pressures and temperatures, as well as corrosive fluids that can cause the surrounding rock to collapse. By installing casing around the wellbore, companies can provide additional support and prevent the well from collapsing. This not only helps to protect the well and its surrounding Environment but also ensures the Safety of workers and equipment on site.

In addition to providing structural support, oil casing also helps to protect the well from external contaminants and prevent fluid migration. Oil wells are often located in harsh environments, such as offshore or in remote locations, where they are exposed to a variety of external factors that can compromise their integrity. By using casing, companies can create a barrier between the wellbore and the surrounding environment, preventing the intrusion of water, gas, or other fluids that could contaminate the well and affect production.

Furthermore, oil casing plays a critical role in well completion and production. Casing is used to isolate different zones within the wellbore, allowing for the controlled extraction of oil and gas from specific reservoirs. By using casing, companies can optimize production and maximize recovery rates, ultimately increasing the overall efficiency of the well. This not only benefits the company in terms of profitability but also helps to ensure the long-term sustainability of the oil industry.

Another important benefit of using oil casing is its contribution to environmental protection. Oil and gas extraction can have a significant impact on the environment, including the potential for groundwater contamination, air pollution, and habitat destruction. By using casing to prevent fluid migration and protect the wellbore, companies can reduce the risk of environmental damage and minimize their overall footprint. This is essential for promoting sustainable development in the oil industry and ensuring that resources are extracted responsibly.

Overall, oil casing plays a vital role in the sustainable development of the oil industry. By providing structural support, protecting the wellbore, and optimizing production, casing helps to ensure the safe and efficient extraction of oil and gas from deep underground reservoirs. Additionally, casing contributes to environmental protection by reducing the risk of contamination and minimizing the industry’s impact on the environment. As the oil industry continues to evolve and face new challenges, the use of oil casing will remain essential for promoting sustainable development and ensuring the long-term viability of the industry.