Table of Contents

Benefits of Using Metal Forming Oil in Copper Extrusion Processes

Metal forming oil technology plays a crucial role in the copper extrusion process, providing numerous benefits that enhance the efficiency and quality of the final product. By understanding the scientific traits of metal forming oil and its impact on copper extrusion processes, manufacturers can optimize their operations and achieve superior results.

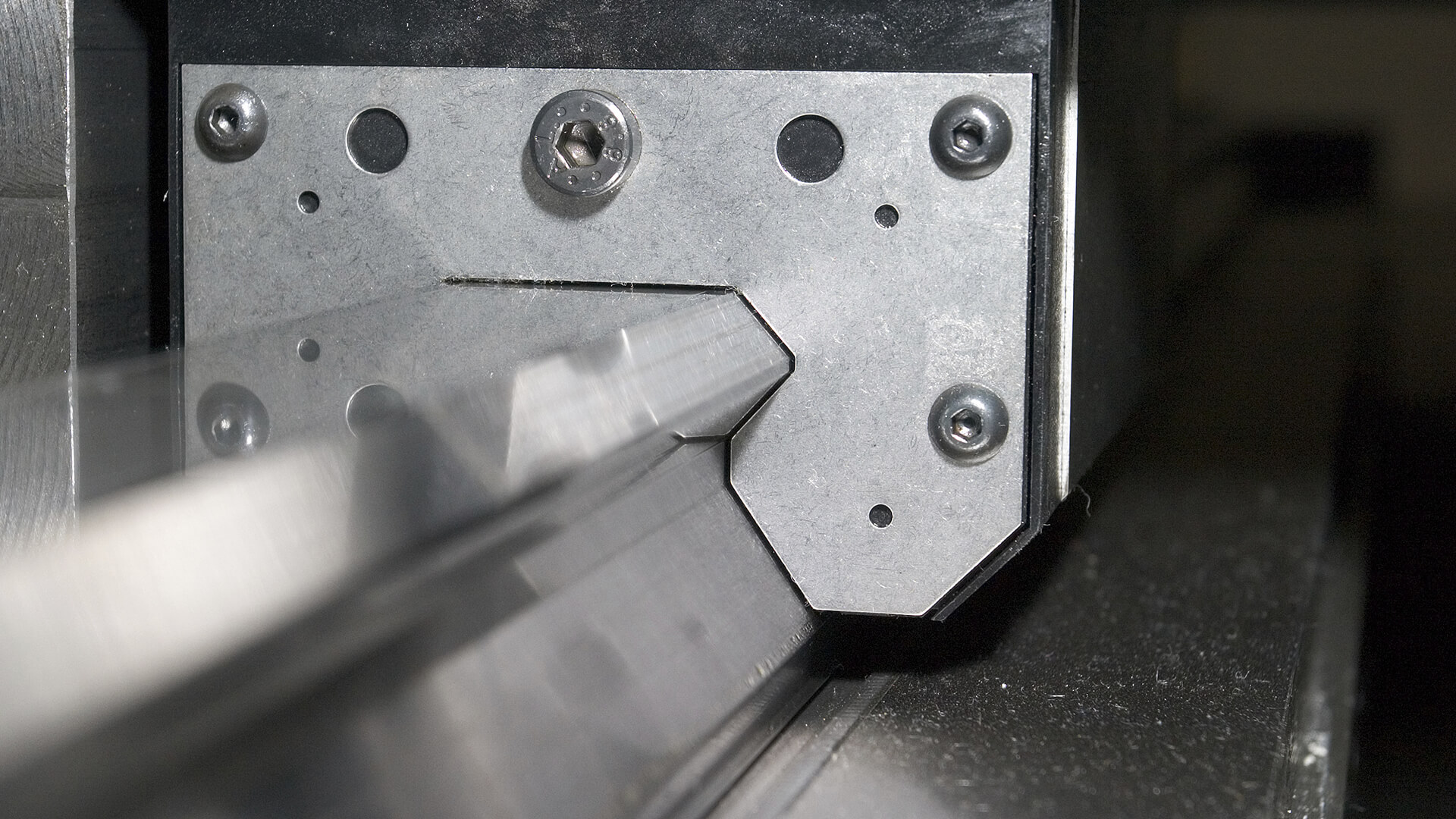

One of the key benefits of using metal forming oil in copper extrusion processes is its lubricating properties. Metal forming oil acts as a barrier between the copper billet and the extrusion die, reducing friction and wear on the equipment. This not only prolongs the lifespan of the extrusion die but also ensures a smoother extrusion process, resulting in a higher quality finished product.

In addition to its lubricating properties, metal forming oil also helps to dissipate heat generated during the extrusion process. Copper is a highly conductive metal that can quickly heat up during extrusion, leading to potential issues such as surface defects or uneven extrusion. By using metal forming oil, manufacturers can control the temperature of the copper billet more effectively, resulting in a more consistent and uniform extrusion.

Furthermore, metal forming oil can improve the flow of the copper material during extrusion, allowing for more complex shapes and designs to be achieved. The viscosity of the oil can be adjusted to suit the specific requirements of the extrusion process, ensuring that the copper material flows smoothly through the die without any interruptions or defects. This level of control is essential for producing high-quality extruded products that meet the exact specifications of the customer.

Another important trait of metal forming oil is its ability to reduce the risk of surface defects on the extruded copper material. Surface defects such as scratches, cracks, or dents can compromise the integrity of the final product and affect its performance. By using metal forming oil, manufacturers can minimize the occurrence of surface defects by providing a protective layer that prevents direct contact between the copper material and the extrusion die.

Moreover, metal forming oil can also improve the overall efficiency of the extrusion process by reducing the amount of energy required to extrude the copper material. The lubricating properties of the oil reduce the friction between the copper billet and the die, allowing for a smoother and more energy-efficient extrusion process. This not only helps to reduce operating costs but also minimizes the environmental impact of the extrusion process.

In conclusion, metal forming oil technology offers a wide range of benefits for copper extrusion processes, including improved lubrication, heat dissipation, flow control, surface defect prevention, and energy efficiency. By understanding the scientific traits of metal forming oil and its impact on the extrusion process, manufacturers can optimize their operations and achieve superior results. With the right metal forming oil, manufacturers can enhance the quality, efficiency, and performance of their extruded copper products, ultimately leading to greater customer satisfaction and business success.

The Role of Lubricants in Enhancing Efficiency and Quality in Copper Extrusion

Metal forming oil technology plays a crucial role in the copper extrusion process, as it helps to enhance efficiency and quality. Copper extrusion is a manufacturing process that involves forcing a copper billet through a die to create a desired shape or profile. Lubricants are used in this process to reduce friction between the copper billet and the die, allowing for smoother extrusion and preventing damage to the equipment.

| Brand | Products |

| www.mogenoils.com/about/ | Lubricating oil |

One of the key scientific traits of metal forming oil technology is its ability to reduce friction. Friction is a major factor that can affect the efficiency and quality of the extrusion process. When there is too much friction between the copper billet and the die, it can Lead to uneven extrusion, surface defects, and even equipment damage. By using the right lubricant, the friction can be minimized, allowing for a more consistent and high-quality extrusion.

In addition to reducing friction, metal forming oil technology also helps to improve the flow of the copper material during extrusion. The lubricant acts as a barrier between the copper billet and the die, allowing the material to flow more smoothly and evenly. This results in a more uniform extrusion and a higher-quality finished product.

Another important scientific trait of metal forming oil technology is its ability to dissipate heat. During the extrusion process, heat is generated due to the friction between the copper billet and the die. If this heat is not properly managed, it can lead to overheating, which can cause the copper material to become brittle and prone to cracking. By using a lubricant that can dissipate heat effectively, the temperature of the extrusion process can be controlled, ensuring that the copper material remains in the optimal state for extrusion.

Furthermore, metal forming oil technology also plays a role in protecting the equipment used in the extrusion process. The lubricant helps to reduce wear and tear on the die and other components of the extrusion machine, prolonging their lifespan and reducing maintenance costs. This not only improves the efficiency of the extrusion process but also helps to ensure the longevity of the equipment.

Overall, metal forming oil technology is a critical component of the copper extrusion process, with its scientific traits playing a key role in enhancing efficiency and quality. By reducing friction, improving material flow, dissipating heat, and protecting equipment, lubricants help to ensure that the extrusion process runs smoothly and produces high-quality copper products. As technology continues to advance, it is likely that metal forming oil technology will continue to evolve, further improving the efficiency and quality of copper extrusion processes.

Innovations in Metal Forming Oil Technology for Improved Copper Extrusion Performance

Metal forming oil technology plays a crucial role in the copper extrusion process, as it helps to reduce friction, improve surface finish, and enhance overall performance. In recent years, there have been significant advancements in metal forming oil technology that have revolutionized the copper extrusion industry. These innovations have led to improved efficiency, productivity, and quality in copper extrusion processes.

One of the key scientific traits of modern metal forming oil technology is its ability to provide superior lubrication. Lubrication is essential in the copper extrusion process to reduce friction between the copper billet and the extrusion die. This helps to prevent wear and tear on the equipment, as well as ensure a smooth and consistent extrusion process. Advanced metal forming oils are formulated with high-quality lubricants that offer superior lubrication properties, resulting in reduced friction and improved extrusion performance.

Another important scientific trait of modern metal forming oil technology is its ability to enhance surface finish. The surface finish of the extruded copper product is critical for its final quality and appearance. Metal forming oils with advanced additives can help to improve the surface finish of the extruded copper, resulting in a smoother and more uniform surface. This not only enhances the aesthetic appeal of the product but also improves its performance and durability.

In addition to lubrication and surface finish, modern metal forming oil technology also offers improved cooling properties. During the extrusion process, the copper billet is subjected to high temperatures, which can affect its mechanical properties. Metal forming oils with enhanced cooling properties help to dissipate heat more effectively, ensuring that the extruded copper product maintains its desired properties. This results in a more consistent and reliable extrusion process, with minimal heat-related issues.

Furthermore, modern metal forming oil technology is designed to be environmentally friendly. With increasing concerns about sustainability and environmental impact, manufacturers are turning to eco-friendly metal forming oils that are biodegradable and non-toxic. These oils not only reduce the environmental footprint of the extrusion process but also provide a safer working Environment for operators. By using environmentally friendly metal forming oils, manufacturers can meet regulatory requirements and demonstrate their commitment to sustainability.

Overall, the scientific traits of modern metal forming oil technology have revolutionized the copper extrusion industry. From superior lubrication and enhanced surface finish to improved cooling properties and environmental sustainability, these innovations have significantly improved the efficiency, productivity, and quality of copper extrusion processes. By incorporating advanced metal forming oils into their operations, manufacturers can achieve higher performance Levels, reduce downtime, and produce high-quality extruded copper products. As technology continues to advance, the future of metal forming oil technology looks promising, with even more innovative solutions on the horizon.