Table of Contents

Benefits of Using Steel Wire Rope in Logging and Forestry Equipment

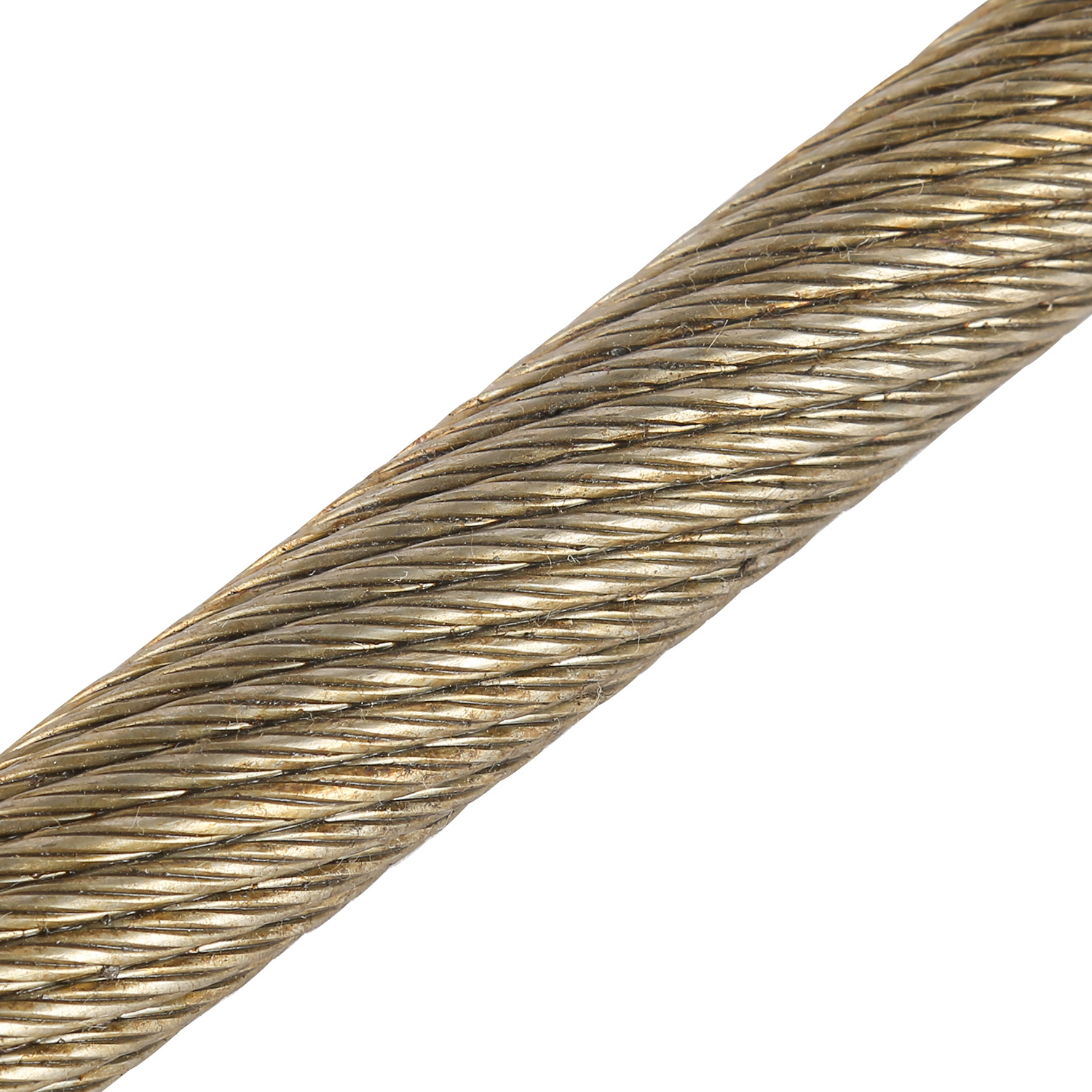

Steel wire rope is a crucial component in the logging and forestry industry, providing strength, durability, and reliability for various equipment and operations. From hauling heavy loads to securing trees during harvesting, steel wire rope plays a vital role in ensuring the Safety and efficiency of logging and forestry operations.

One of the key benefits of using steel wire rope in logging and forestry equipment is its exceptional strength. Steel wire rope is known for its high tensile strength, making it capable of withstanding heavy loads and intense pressure. This strength is essential in logging and forestry operations, where equipment needs to handle large and heavy Logs, machinery, and other materials. Steel wire rope provides the necessary support and stability to ensure that operations run smoothly and safely.

In addition to its strength, steel wire rope is also highly durable. The harsh conditions of logging and forestry operations, such as exposure to moisture, dirt, and extreme temperatures, can take a toll on equipment. Steel wire rope is resistant to corrosion and abrasion, making it well-suited for these challenging environments. Its durability ensures that it can withstand the rigors of daily use without compromising its performance or safety.

Furthermore, steel wire rope is known for its reliability. In logging and forestry operations, equipment failure can have serious consequences, including injuries, damage to property, and delays in production. Steel wire rope’s reliability gives operators peace of mind, knowing that their equipment is dependable and can be trusted to perform consistently under demanding conditions. This reliability is essential for maintaining the safety and efficiency of logging and forestry operations.

Another benefit of using steel wire rope in logging and forestry equipment is its versatility. Steel wire rope comes in a variety of sizes, configurations, and constructions, allowing operators to choose the right type of rope for their specific needs. Whether it’s for lifting, towing, or securing loads, there is a steel wire rope that can meet the requirements of different applications in the logging and forestry industry. This versatility makes steel wire rope a valuable asset for operators looking to optimize their equipment and operations.

Moreover, steel wire rope is cost-effective in the long run. While the initial investment in steel wire rope may be higher than other types of rope, its durability and longevity make it a cost-effective choice over time. Steel wire rope requires less frequent replacement and maintenance compared to other types of rope, reducing downtime and expenses associated with equipment repair and replacement. This cost-effectiveness makes steel wire rope a smart investment for logging and forestry operators looking to maximize their resources and minimize operational costs.

In conclusion, steel wire rope offers a range of benefits for logging and forestry equipment, including exceptional strength, durability, reliability, versatility, and cost-effectiveness. Its ability to withstand heavy loads, harsh conditions, and demanding operations makes it an essential component in ensuring the safety and efficiency of logging and forestry operations. By choosing steel wire rope for their equipment, operators can trust that their operations will run smoothly and effectively, leading to increased productivity and success in the logging and forestry industry.

Maintenance Tips for Steel Wire Rope in Logging and Forestry Equipment

Steel wire rope is an essential component of logging and forestry equipment, providing the strength and durability needed to handle heavy loads and withstand harsh environmental conditions. Proper maintenance of steel wire rope is crucial to ensure the safety and efficiency of logging and forestry operations. In this article, we will discuss some important tips for maintaining steel wire rope in logging and forestry equipment.

One of the most important aspects of steel wire rope maintenance is regular inspection. Inspecting the rope for signs of wear, corrosion, or damage is essential to prevent accidents and ensure the safe operation of equipment. Inspections should be conducted before each use and after any significant use or exposure to harsh conditions. Look for broken wires, kinks, or other signs of damage that could compromise the integrity of the rope.

In addition to visual inspections, it is also important to regularly lubricate steel wire rope to prevent corrosion and extend its lifespan. Lubrication helps to reduce friction between the individual wires, preventing them from rubbing against each other and causing premature wear. Use a high-quality lubricant specifically designed for steel wire rope, and apply it evenly along the entire length of the rope.

Another important maintenance tip for steel wire rope is to avoid overloading. Exceeding the recommended weight capacity of the rope can cause it to stretch, weaken, or even break under the strain. Always check the manufacturer’s guidelines for the maximum load capacity of the rope and never exceed this limit. Overloading not only puts the safety of workers at risk but also shortens the lifespan of the rope.

Proper storage of steel wire rope is also crucial for maintaining its integrity. Store the rope in a dry, well-ventilated area away from direct sunlight and moisture. Avoid storing the rope in a coiled or twisted position, as this can cause kinks and damage to the individual wires. Instead, hang the rope on a rack or reel to keep it straight and prevent tangling.

Regularly inspecting and maintaining the end fittings of steel wire rope is another important aspect of maintenance. End fittings, such as Thimbles, Shackles, and Hooks, are critical for securing the rope to equipment and ensuring safe operation. Inspect the end fittings for signs of wear, corrosion, or damage, and replace any worn or damaged fittings immediately.

In conclusion, proper maintenance of steel wire rope is essential for the safe and efficient operation of logging and forestry equipment. Regular inspections, lubrication, avoiding overloading, proper storage, and maintaining end fittings are all important aspects of steel wire rope maintenance. By following these tips, you can ensure the longevity and reliability of your steel wire rope, keeping your equipment running smoothly and safely for years to come.

Safety Precautions When Using Steel Wire Rope in Logging and Forestry Equipment

Steel wire rope is a crucial component in logging and forestry equipment, providing strength and durability for various tasks in these industries. However, it is essential to follow safety precautions when using steel wire rope to prevent accidents and injuries. In this article, we will discuss some important safety measures to keep in mind when working with steel wire rope in logging and forestry equipment.

First and foremost, it is crucial to inspect the steel wire rope regularly for any signs of wear and tear. This includes checking for broken strands, kinks, or corrosion that could weaken the rope and Lead to failure. Any damaged sections should be replaced immediately to ensure the safety of the equipment and the workers using it.

When using steel wire rope in logging and forestry equipment, it is important to ensure that the rope is properly secured and anchored. This helps prevent the rope from slipping or coming loose during operation, which could result in serious accidents. Additionally, using the appropriate size and type of fittings and attachments is essential to ensure a secure connection between the rope and the equipment.

Another important safety precaution when using steel wire rope is to avoid overloading the rope beyond its rated capacity. Exceeding the maximum load limit can cause the rope to stretch or break, putting workers at risk of injury. It is crucial to know the weight limits of the equipment and the capabilities of the steel wire rope to prevent overloading and ensure safe operation.

Proper handling and storage of steel wire rope are also essential for maintaining its integrity and safety. When not in use, the rope should be stored in a dry, clean area away from moisture and Chemicals that could cause corrosion. Additionally, the rope should be handled with care to prevent kinks or twists that could weaken the strands and compromise its strength.

When using steel wire rope in logging and forestry equipment, it is important to follow proper lifting and rigging techniques to prevent accidents. This includes using the correct rigging configurations, angles, and attachments to ensure a safe and secure lift. Workers should also be trained on how to properly operate the equipment and handle the steel wire rope to minimize the risk of accidents.

In conclusion, safety precautions are essential when using steel wire rope in logging and forestry equipment to prevent accidents and injuries. Regular inspection, proper anchoring, avoiding overloading, and following proper handling and storage practices are crucial for maintaining the integrity and safety of the rope. By following these safety measures and guidelines, workers can ensure a safe and efficient operation when using steel wire rope in logging and forestry equipment.