Table of Contents

Benefits of Using Asphalt Anti-Stripping Additives

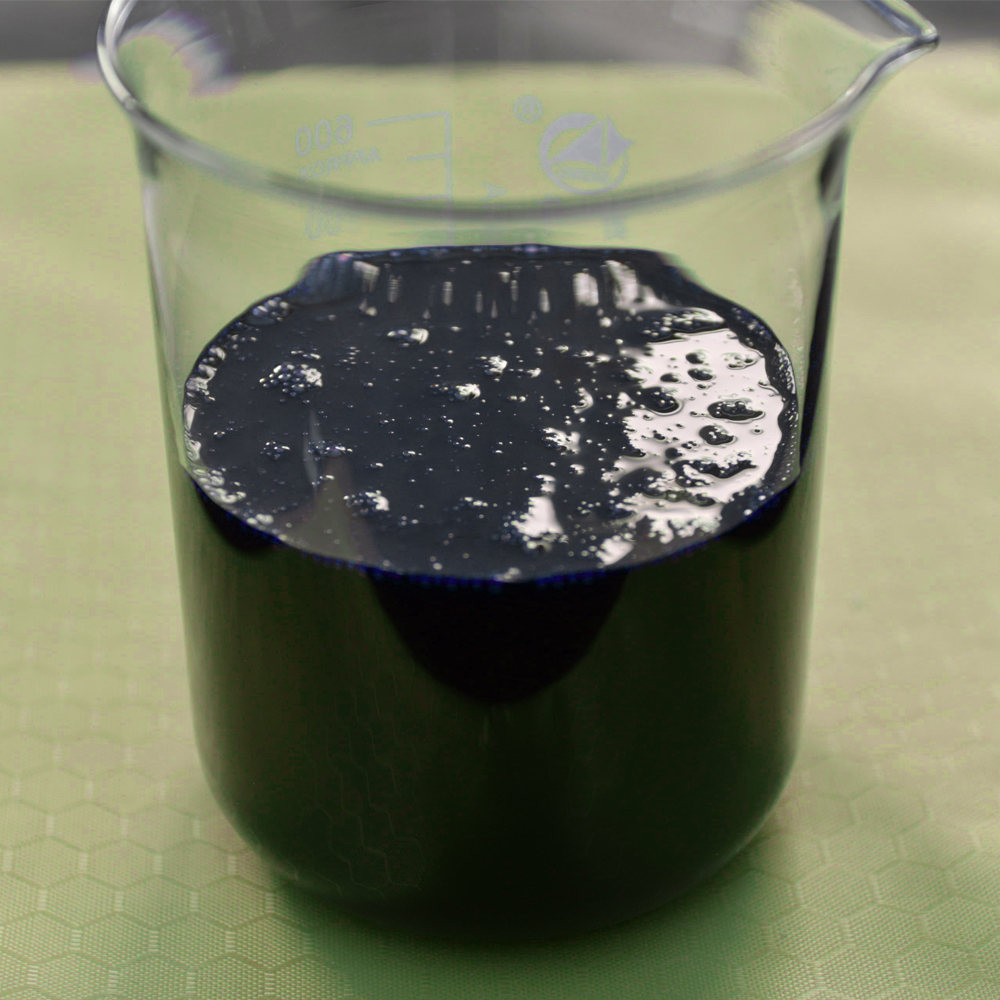

Asphalt anti-stripping additives, also known as bitumen bonding agents, are essential components in the construction and maintenance of asphalt pavements. These additives play a crucial role in preventing moisture damage and improving the overall performance and durability of asphalt surfaces. In this article, we will explore the benefits of using asphalt anti-stripping additives and how they contribute to the longevity and quality of asphalt pavements.

One of the primary benefits of using asphalt anti-stripping additives is their ability to enhance the bond between the asphalt binder and the aggregate particles. When asphalt pavements are exposed to moisture, the bond between the binder and aggregate can weaken, leading to stripping and premature pavement failure. By incorporating anti-stripping additives into the asphalt mix, the bond between the binder and aggregate is strengthened, reducing the risk of moisture damage and improving the overall performance of the pavement.

In addition to improving bond strength, asphalt anti-stripping additives also help to increase the resistance of asphalt pavements to moisture damage. When water infiltrates the pavement structure, it can cause the asphalt binder to become soft and lose its adhesive properties, leading to rutting, cracking, and other forms of distress. By using anti-stripping additives, the asphalt binder is better able to resist the effects of moisture, resulting in a more durable and long-lasting pavement surface.

Furthermore, asphalt anti-stripping additives can also improve the workability and compactability of the asphalt mix. These additives help to reduce the viscosity of the asphalt binder, making it easier to work with during the mixing and placement process. This can Lead to more efficient construction practices, reduced construction time, and improved pavement quality.

| Part | Item |

| 1 | msds anti strip asphalt additive |

Another benefit of using asphalt anti-stripping additives is their ability to enhance the overall performance of the pavement in terms of resistance to rutting, cracking, and fatigue. By improving the bond between the binder and aggregate, these additives help to distribute loads more evenly across the pavement structure, reducing the risk of distress and extending the service life of the pavement.

In conclusion, asphalt anti-stripping additives play a critical role in the construction and maintenance of asphalt pavements. These additives help to improve bond strength, increase resistance to moisture damage, enhance workability and compactability, and improve overall pavement performance. By incorporating anti-stripping additives into asphalt mixes, contractors and engineers can ensure the longevity and quality of asphalt pavements, ultimately saving time and money in the long run. Whether it’s a new construction project or a pavement rehabilitation project, the benefits of using asphalt anti-stripping additives are clear, making them a valuable tool in the toolbox of any pavement professional.

Importance of Bitumen Bonding Agents in Pavement Construction

Bitumen bonding agents, also known as asphalt anti-stripping additives, play a crucial role in pavement construction. These additives are designed to improve the adhesion between bitumen and aggregate, ultimately enhancing the durability and performance of the pavement. In this article, we will explore the importance of bitumen bonding agents in pavement construction and how they contribute to the overall quality of the road surface.

One of the key benefits of using bitumen bonding agents is their ability to prevent stripping, which is a common issue in asphalt pavements. Stripping occurs when the bond between bitumen and aggregate is weak, leading to the separation of the two materials. This can result in the formation of potholes, cracks, and other pavement defects, compromising the structural integrity of the road. By using a bitumen bonding agent, the adhesion between bitumen and aggregate is significantly improved, reducing the risk of stripping and enhancing the overall performance of the pavement.

In addition to preventing stripping, bitumen bonding agents also help to improve the overall durability of the pavement. By enhancing the bond between bitumen and aggregate, these additives create a stronger, more resilient pavement surface that can withstand heavy traffic loads, harsh weather conditions, and other environmental factors. This increased durability not only extends the lifespan of the pavement but also reduces the need for costly repairs and maintenance in the future.

Furthermore, bitumen bonding agents can also improve the skid resistance of the pavement, making it safer for drivers and pedestrians. A strong bond between bitumen and aggregate helps to create a smoother, more uniform surface that offers better traction and grip, reducing the risk of accidents and improving overall road Safety. This is particularly important in areas with high traffic volumes or challenging driving conditions, where skid resistance is essential to prevent accidents and ensure the smooth flow of traffic.

Another important benefit of using bitumen bonding agents is their ability to enhance the overall quality of the pavement. By improving the adhesion between bitumen and aggregate, these additives help to create a more uniform, stable pavement surface that is free from defects and imperfections. This not only improves the aesthetic appearance of the road but also enhances its performance and longevity, ensuring that it remains in good condition for years to come.

In conclusion, bitumen bonding agents play a crucial role in pavement construction by improving the adhesion between bitumen and aggregate, preventing stripping, enhancing durability, improving skid resistance, and enhancing overall pavement quality. By using these additives, contractors can create stronger, more resilient pavements that offer better performance, longevity, and safety for drivers and pedestrians. As such, bitumen bonding agents are an essential component of any pavement construction project and should be carefully selected and applied to ensure the best possible results.