Table of Contents

Ağır Hizmet Uygulamalarında Kelepçeli Çelik Halat Kullanmanın Faydaları

Köstekli tel halat, çeşitli endüstrilerdeki ağır hizmet uygulamalarında yaygın olarak kullanılan çok yönlü ve dayanıklı bir araçtır. Tel halat ve kelepçe kombinasyonu, ağır yükleri kaldırmak, çekmek veya sabitlemek için güvenli ve güvenilir bir yol sağlar. Kelepçe, tel halat ile yük arasında bir bağlantı noktası görevi görerek yükün emniyetli ve emniyetli bir şekilde bağlanmasını sağlar.

Köstekli tel halat kullanmanın en önemli faydalarından biri de sağlamlığı ve dayanıklılığıdır. Tel halat, güçlü ve esnek bir kablo oluşturmak üzere birlikte bükülmüş birden fazla çelik telden oluşur. Bu yapı, tel halatın yüksek yüklere dayanmasına ve aşınmaya karşı direnç göstermesine olanak tanır, bu da onu ağır hizmet uygulamaları için ideal kılar. Kelepçe ile birleştirildiğinde tel halat, kırılma veya arızalanma riski olmaksızın ağır yükleri güvenli bir şekilde tutabilir ve kaldırabilir.

Köstekli tel halat, dayanıklılığının yanı sıra oldukça çok yönlüdür. Kelepçe tel halata kolayca takılıp çıkarılabilir, böylece yük bağlantılarında hızlı ve etkili değişiklikler yapılabilir. Bu esneklik, kelepçeli tel halatı, yüklerin sık sık taşınması veya sabitlenmesi gereken endüstrilerde değerli bir araç haline getirir.

Köstekli tel halat kullanmanın bir diğer yararı da güvenilirliğidir. Kelepçe, tel halat ile yük arasında güvenli bir bağlantı noktası görevi görerek yükün güvenli bir şekilde bağlanmasını ve kaldırma veya çekme sırasında gevşememesini sağlar. Bu güvenilirlik, çalışanların ve ekipmanların güvenliğinin çok önemli olduğu ağır iş uygulamalarında hayati önem taşır.

Ayrıca, kelepçeli tel halat uygun maliyetlidir. Tel halatın dayanıklılığı ve uzun ömürlülüğü, ağır kullanıma dayanabileceği ve uzun süre dayanabileceği anlamına gelir ve sık sık değiştirme ihtiyacını azaltır. Bu, operasyonlarında kelepçeli tel halat kullanan işletmeler için maliyet tasarrufu sağlayabilir.

Ağır iş uygulamaları için kelepçeli tel halat seçerken, işin özel gereksinimlerini dikkate almak önemlidir. Uygun tel halat ve kelepçe kombinasyonunu seçerken yükün ağırlığı, tel halatın kullanılacağı ortam ve kullanım sıklığı gibi faktörlerin tümü dikkate alınmalıdır.

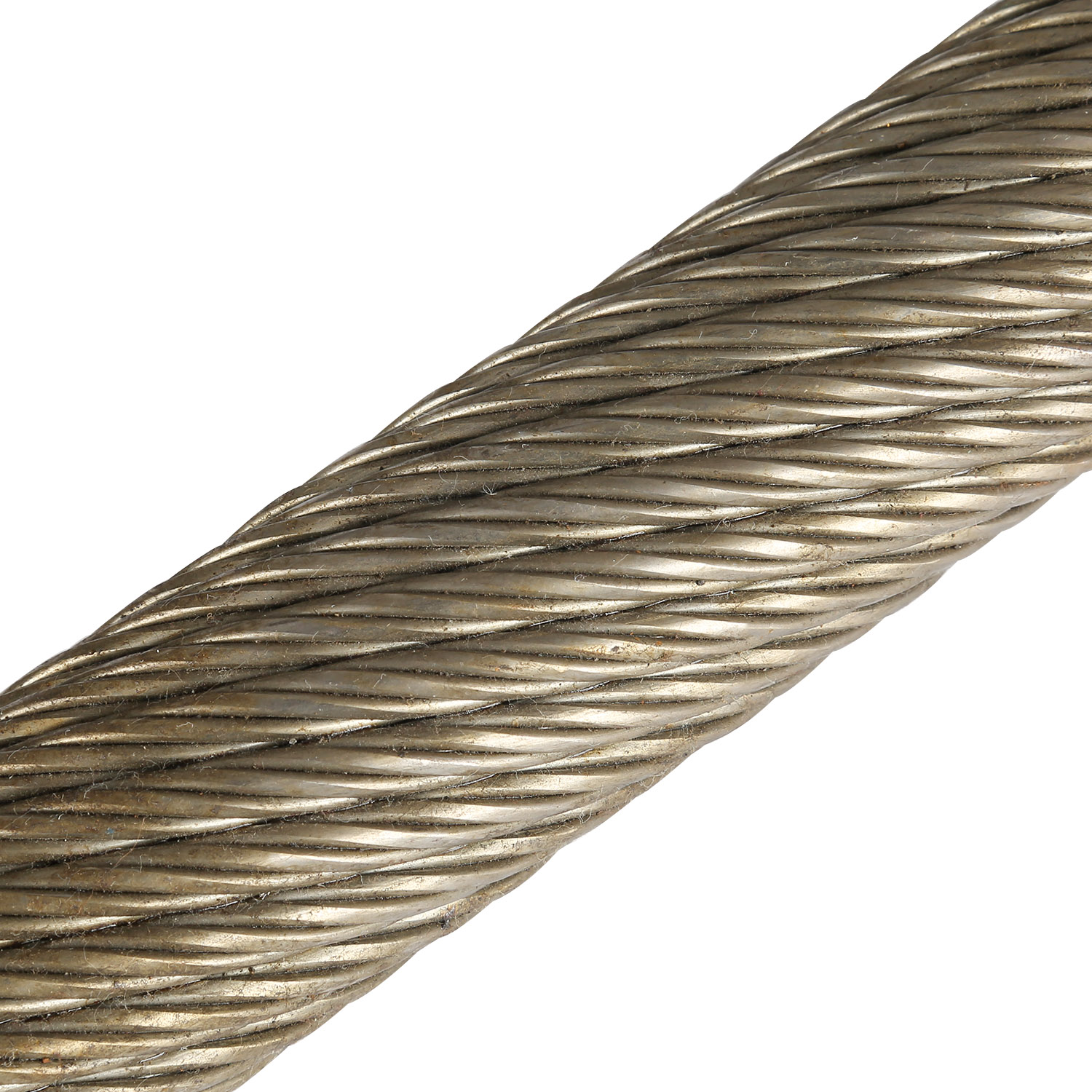

Yandaki çelik kablo da başka bir kullanışlı araçtır. Kelepçeli tel halatla birlikte kullanılabilir. Çelik kablo, birlikte bükülmüş çelik tellerden yapılmış güçlü ve dayanıklı bir kablodur. Tel halat gibi çelik kablo da güç ve dayanıklılığın gerekli olduğu ağır hizmet uygulamaları için idealdir. Çelik kablo, kelepçeli tel halatla birlikte kullanıldığında, ağır yüklerin kaldırılması veya çekilmesi için ek destek ve güvenlik sağlayabilir.

Sonuç olarak, kelepçeli tel halat, çeşitli endüstrilerdeki ağır iş uygulamaları için değerli bir araçtır. Gücü, dayanıklılığı, çok yönlülüğü, güvenilirliği ve maliyet etkinliği, onu ağır yüklerin kaldırılması, çekilmesi ve sabitlenmesi için önemli bir bileşen haline getiriyor. Kelepçeli tel halat, yakında çelik kabloyla birlikte kullanıldığında zorlu görevler için daha da fazla destek ve güvenlik sağlayabilir. Ağır kaldırma ve çekme işlemlerine dayanan işletmeler, kelepçeli tel halat kullanımından büyük ölçüde faydalanabilir, böylece verimliliği ve üretkenliği en üst düzeye çıkarırken çalışanların ve ekipmanın güvenliğini sağlar.

Güvenlik Açısından Yakındaki Çelik Kablonun Bakımı ve Denetlenmesi

Çelik kablolar birçok endüstride çok önemli bir bileşendir ve çeşitli uygulamalar için güç ve dayanıklılık sağlar. Ağır yükleri kaldırmak, ekipmanı sabitlemek veya inşaat projelerinde destek sağlamak için kullanılsa da, çelik kabloların güvenlik ve güvenilirliği sağlamak için uygun şekilde bakımı yapılmalı ve denetlenmelidir. Bu makalede, çelik kabloların bakım ve incelemesinin önemini tartışacağız ve bunun nasıl etkili bir şekilde yapılacağına dair bazı ipuçları vereceğiz.

Endüstriyel ortamlarda kullanılan en yaygın çelik kablo türlerinden biri tel halattır. Tel halat, güçlü ve esnek bir kablo oluşturmak üzere birlikte bükülmüş birden fazla çelik telden oluşur. Bir kelepçeyle birlikte kullanıldığında tel halat, ağır yükleri kaldırmak veya ekipmanı yerinde sabitlemek için kullanılabilir. Ancak zamanla tel halat aşınabilir veya hasar görebilir, bu da sağlamlığını ve güvenliğini tehlikeye atabilir.

Halatın bakımını uygun şekilde yapmak için, tel halatı aşınma ve hasar belirtileri açısından düzenli olarak incelemek önemlidir. Bu, ipin tüm uzunluğunun kırık teller, bükülmeler veya diğer anormallikler açısından görsel olarak incelenmesiyle yapılabilir. Buna ek olarak, halatın bir kelepçeye veya başka bir donanıma bağLandığı uçlarının aşınma veya korozyon belirtileri açısından kontrol edilmesi önemlidir.

Görsel incelemelere ek olarak, telin mukavemetinin periyodik olarak test edilmesi de önemlidir. Halat, amaçlanan yükü hala destekleyebildiğinden emin olmak için. Bu, halattaki gerilimi ölçmek için bir gerilim ölçer veya başka bir test ekipmanı kullanılarak yapılabilir. Gerilim önerilen seviyenin altındaysa olası bir arızayı önlemek için tel halat derhal değiştirilmelidir.

Endüstriyel ortamlarda tel halatın yanı sıra çelik kablolar da yaygın olarak kullanılmaktadır. Çelik kablolar genellikle güçlü ve dayanıklı bir kablo oluşturmak üzere birlikte bükülmüş birden fazla çelik telden oluşur. Tel halatlar gibi çelik kabloların da güvenliği ve güvenilirliği sağlamak için uygun şekilde bakımı yapılmalı ve incelenmelidir.

Çelik kabloların bakımının en önemli yönlerinden biri, bunları aşınma ve hasar belirtileri açısından düzenli olarak incelemektir. Bu, kablonun tüm uzunluğunun kırık teller, bükülmeler veya diğer anormallikler açısından görsel olarak incelenmesiyle yapılabilir. Ayrıca kablonun donanıma bağlandığı uçlarında aşınma veya korozyon belirtileri olup olmadığını kontrol etmek önemlidir.

Görsel incelemelere ek olarak, çelik kablonun sağlamlığını periyodik olarak test etmek de önemlidir. hala amaçlanan yükü destekleme kapasitesine sahiptir. Bu, kablodaki gerilimi ölçmek için bir gerilim ölçer veya başka bir test ekipmanı kullanılarak yapılabilir. Gerginlik önerilen seviyenin altındaysa olası bir arızayı önlemek için çelik kablo derhal değiştirilmelidir.

Sonuç olarak, endüstriyel ortamlarda güvenlik ve güvenilirliğin sağlanması için çelik kabloların uygun şekilde bakımı ve muayenesi şarttır. Tel halatları ve çelik kabloları aşınma ve hasar belirtileri açısından düzenli olarak inceleyerek ve bunların sağlamlığını periyodik olarak test ederek, kazaların önlenmesine yardımcı olabilir ve ekipmanınızın güvenli ve verimli bir şekilde çalışmasını sağlayabilirsiniz. Çelik kablolarla çalışırken güvenliğin her zaman en önemli öncelik olması gerektiğini unutmayın; bu nedenle kendinizi ve başkalarını korumak için kabloların bakımını ve incelemesini doğru şekilde yapmaya zaman ayırın.

Çeşitli Endüstrilerde 100 ft. Çelik Halatların En Önemli Kullanım Alanları ve Avantajları

Çelik tel halat 100 ft., çeşitli endüstrilerde uygulama alanı bulan çok yönlü ve dayanıklı bir araçtır. Gücü ve esnekliği, ağır yüklerin kaldırılması, çekilmesi ve sabitlenmesi için onu ideal bir seçim haline getirir. Bu makalede, 100 ft. çelik tel halatın farklı endüstrilerdeki en önemli kullanım alanlarını ve avantajlarını keşfedeceğiz.

100 ft. çelik tel halatın başlıca kullanımlarından biri inşaat sektörüdür. İnşaat sahaları genellikle ağır malzemelerin ve ekipmanların kaldırılmasını ve taşınmasını gerektirir. 100 ft’lik çelik tel halat, bu yükleri güvenli bir şekilde kaldırmak ve taşımak için gerekli gücü ve güvenilirliği sağlar. Esnekliği, dar alanlarda ve engellerin etrafında gezinmesine olanak tanır ve bu da onu inşaat projeleri için değerli bir araç haline getirir.

100 ft. çelik tel halat kullanımından yararlanan diğer bir endüstri de denizcilik ve denizcilik endüstrisidir. Gemiler ve tekneler demirleme, çekme ve demirleme için çelik tel halatlara güvenir. Çelik tel halatın dayanıklılığı, denizin zorlu koşullarına dayanabilmesini sağlar ve bu da onu denizcilik uygulamaları için güvenilir bir seçim haline getirir.

Madencilik endüstrisinde, 100 ft. çelik tel halat, yer altı madenlerinde malzemelerin kaldırılması ve taşınması için kullanılır. . Çelik tel halatın gücü, madencilik faaliyetlerinde karşılaşılan ağır yüklerin üstesinden gelmesini sağlar. Esnekliği ve aşınmaya karşı direnci, onu madencilik ortamlarının zorlu koşullarına çok uygun hale getirir.

100 ft. çelik tel halat, petrol ve gaz endüstrisinde de yaygın olarak kullanılır. Açık deniz sondaj platformları, ekipmanı ve malzemeleri platforma kaldırmak ve platformdan kaldırmak için çelik tel halat gerektirir. Çelik tel halatların korozyona dayanıklı özellikleri, onu tuzlu suya maruz kalmanın endişe verici olduğu açık deniz uygulamaları için ideal bir seçim haline getiriyor.

Otomotiv endüstrisi ayrıca çeşitli uygulamalar için 100 ft. çelik halatlara güveniyor. Otomobil üreticileri, ağır bileşenleri kaldırmak ve taşımak için montaj sürecinde çelik tel halat kullanıyor. Çelik tel halat aynı zamanda çekme ve kurtarma operasyonlarında da kullanılarak araçları güvenli bir şekilde çekmek için gereken gücü ve güvenilirliği sağlar.

100 ft. çelik tel halatların en önemli avantajlarından biri dayanıklılığıdır. Çelik tel halat korozyona, aşınmaya ve aşırı sıcaklıklara karşı dayanıklıdır, bu da onu endüstriyel uygulamalar için uzun ömürlü ve güvenilir bir seçenek haline getirir. Yüksek gerilme mukavemeti, ağır yükleri esnemeden veya kırılmadan kaldırmasına olanak tanıyarak işçilerin ve ekipmanların güvenliğini sağlar.

100 ft. çelik tel halatın bakımı ve incelenmesi de kolaydır. Düzenli denetimler, herhangi bir aşınma veya hasar belirtisinin tespit edilmesine yardımcı olarak zamanında onarım veya değiştirme yapılmasına olanak sağlar. Çelik tel halatların doğru şekilde bakımı, ömrünü uzatabilir ve çeşitli endüstrilerde güvenilirliğinin devam etmesini sağlayabilir.

Sonuç olarak, 100 ft. çelik tel halat, çok çeşitli endüstrilerde uygulama alanı bulan çok yönlü ve dayanıklı bir araçtır. Gücü, esnekliği ve dayanıklılığı, onu ağır yüklerin kaldırılması, çekilmesi ve sabitlenmesi için ideal bir seçim haline getirir. İnşaat, denizcilik, madencilik, petrol ve gaz, otomotiv veya diğer endüstrilerde olsun, 100 ft. çelik tel halat endüstriyel uygulamalar için gereken gücü ve güvenilirliği sağlayan değerli bir varlıktır.