Table of Contents

The Process of Manufacturing PVC Ropes

PVC ropes are a versatile and durable type of Rope that is commonly used in a variety of applications, from construction to outdoor recreation. The process of manufacturing PVC ropes involves several steps that require precision and attention to detail.

The first step in the manufacturing process is the selection of raw materials. PVC, or polyvinyl chloride, is the primary material used to make PVC ropes. PVC is a synthetic plastic Polymer that is known for its durability and resistance to weathering and Chemicals. In addition to PVC, other materials such as plasticizers, Stabilizers, and colorants may also be added to the mix to enhance the properties of the final product.

Once the raw materials have been selected, they are mixed together in a process known as compounding. During compounding, the PVC resin is combined with the other additives in a high-speed mixer to create a uniform mixture. The mixture is then heated to a specific temperature to melt the PVC resin and allow it to blend with the other ingredients.

After compounding, the PVC mixture is extruded through a die to form the shape of the rope. The extrusion process involves forcing the molten PVC mixture through a shaped opening to create a continuous length of rope. The size and shape of the die determine the diameter and texture of the finished rope.

Once the rope has been extruded, it is cooled and solidified to set its shape. This cooling process may involve passing the rope through a water bath or air Cooling System to reduce its temperature and harden the PVC material. After cooling, the rope is cut to the desired length and wound onto spools for storage and transportation.

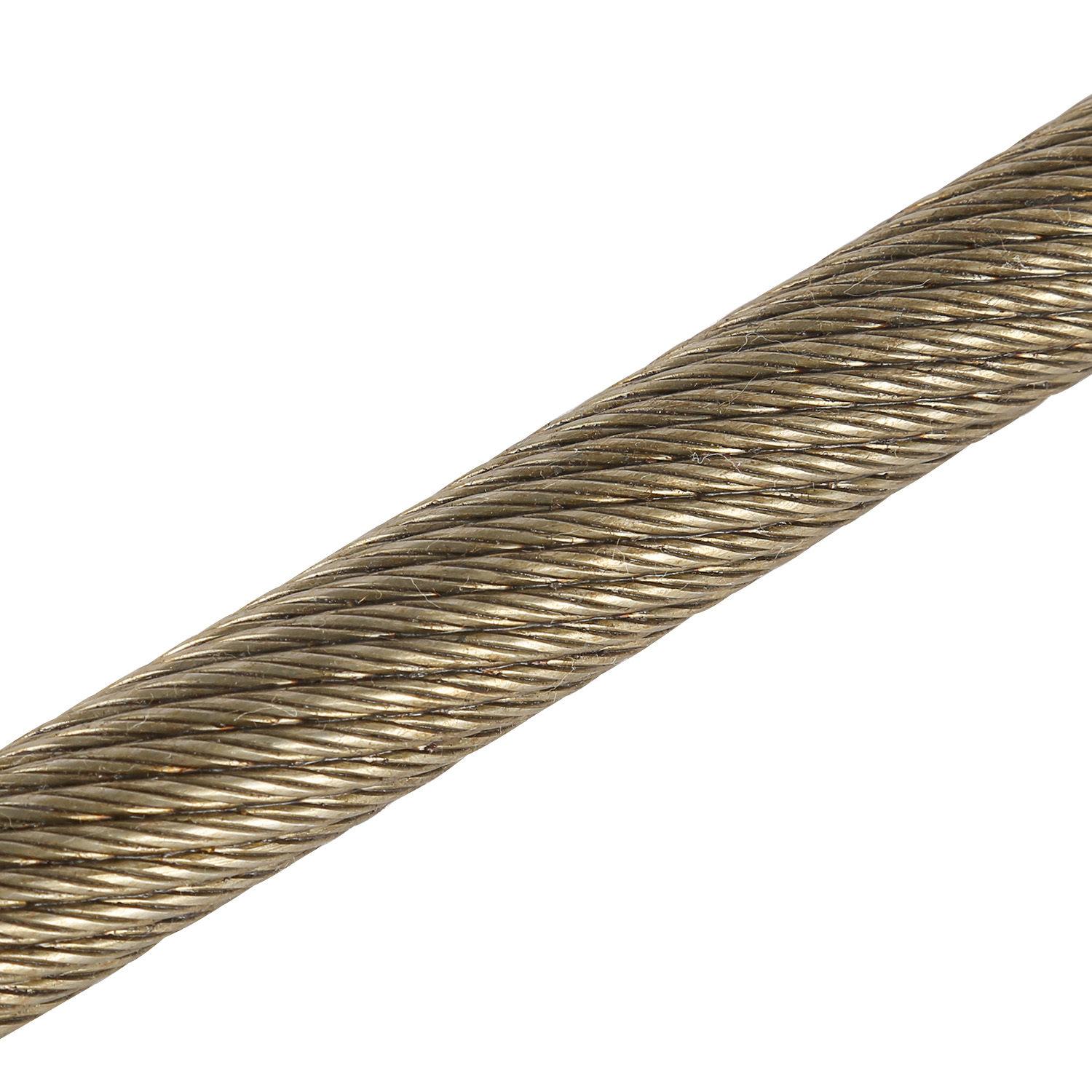

In some cases, the PVC rope may undergo additional processing steps to enhance its properties. For example, the rope may be coated with a layer of nylon to improve its strength and abrasion resistance. Nylon coated steel wire rope is a popular choice for applications that require a high level of durability and flexibility.

Overall, the process of manufacturing PVC ropes is a complex and precise operation that requires careful attention to detail. From selecting the raw materials to extruding and cooling the rope, each step in the process plays a crucial role in producing a high-quality product. By following strict quality control measures and using advanced manufacturing techniques, manufacturers can ensure that PVC ropes meet the highest standards of performance and reliability.

In conclusion, PVC ropes are an essential component in many industries, from construction to sports and recreation. The process of manufacturing PVC ropes involves several key steps, including compounding, extrusion, cooling, and finishing. By using high-quality materials and advanced manufacturing techniques, manufacturers can produce PVC ropes that are strong, durable, and versatile. Whether used for lifting heavy loads or securing equipment, PVC ropes are a reliable and cost-effective solution for a wide range of applications.

The Benefits of Using Nylon Coated Steel Wire Rope

Nylon coated steel wire rope is a versatile and durable material that is used in a wide range of applications. From construction to marine industries, this type of wire rope offers many benefits that make it a popular choice for various projects.

One of the key advantages of nylon coated steel wire rope is its strength and durability. The steel core provides the necessary strength to support heavy loads, while the nylon coating adds an extra layer of protection against corrosion and wear. This makes it an ideal choice for applications where the wire rope will be exposed to harsh environments or frequent use.

In addition to its strength, nylon coated steel wire rope is also flexible and easy to work with. This makes it a versatile material that can be used in a variety of applications, from lifting and rigging to fencing and netting. The flexibility of the wire rope allows it to bend and twist without losing its strength, making it a reliable choice for projects that require precision and accuracy.

Another benefit of nylon coated steel wire rope is its resistance to abrasion and wear. The nylon coating helps to protect the steel core from damage caused by friction and rubbing, extending the lifespan of the wire rope and reducing the need for frequent replacements. This can result in cost savings for businesses that rely on wire rope for their operations.

Furthermore, nylon coated steel wire rope is resistant to chemicals and UV rays, making it suitable for outdoor and marine applications. The nylon coating helps to protect the steel core from exposure to harsh chemicals and sunlight, ensuring that the wire rope remains strong and reliable in any Environment. This makes it a popular choice for projects that require a durable and long-lasting material.

Overall, nylon coated steel wire rope offers a range of benefits that make it a valuable material for a variety of applications. Its strength, durability, flexibility, and resistance to abrasion and wear make it a reliable choice for projects that require a high-quality wire rope. Whether used in construction, marine, or industrial settings, nylon coated steel wire rope is a versatile and dependable material that can help to ensure the success of any project.

In conclusion, nylon coated steel wire rope is a versatile and durable material that offers many benefits for a wide range of applications. Its strength, flexibility, resistance to abrasion and wear, and protection against chemicals and UV rays make it a reliable choice for projects that require a high-quality wire rope. Whether used in lifting and rigging, fencing and netting, or other applications, nylon coated steel wire rope is a valuable material that can help to ensure the success of any project.