目录

The Process of Manufacturing Brake Pads Steel Back Plates

Brake pads are an essential component of any vehicle’s braking system, providing the necessary friction to slow Down or stop the vehicle when the brakes are applied. One crucial part of a brake Pad is the steel back plate, which provides structural support and stability to the pad. In this article, we will explore the process of manufacturing brake pads steel back plates in a factory setting.

The first step in manufacturing brake pads steel back plates is to procure the raw materials needed for the process. This typically includes high-quality steel sheets that are cut to the required dimensions for the back plates. The steel sheets are then cleaned and prepared for the next stage of the manufacturing process.

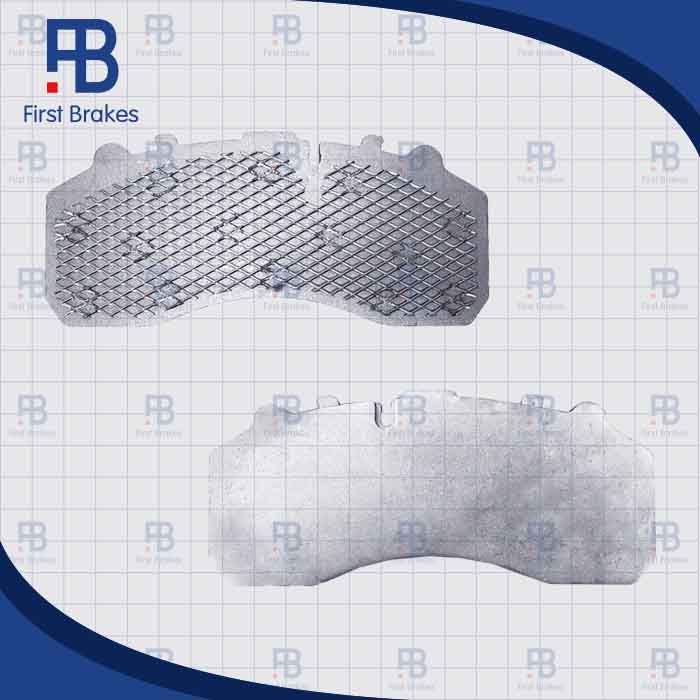

Once the steel sheets are ready, they are fed into a stamping machine that cuts and shapes the steel into the desired back plate design. The stamping machine uses a die to press the steel sheets into the correct shape, ensuring precision and consistency in the manufacturing process. This step is crucial in creating back plates that meet the exact specifications required for brake pads.

After the back plates are stamped, they are subjected to a heat treatment process to strengthen the steel and improve its durability. This involves heating the back plates to a specific temperature and then cooling them slowly to achieve the desired hardness and toughness. Heat treatment is essential to ensure that the back plates can withstand the high temperatures and pressures generated during braking.

Once the back plates have been heat-treated, they are inspected for quality control purposes. This involves checking the dimensions, surface finish, and overall integrity of the back plates to ensure that they meet the required standards. Any back plates that do not meet the quality criteria are rejected and sent back for rework or disposal.

After passing the quality control inspection, the back plates are coated with a protective layer to prevent corrosion and improve their longevity. This coating can be a paint or a specialized coating that is designed to withstand the harsh conditions of the braking system. The back plates are then cured in an oven to ensure that the coating adheres properly to the steel surface.

Once the coating has been applied and cured, the back plates are ready for final assembly. This involves attaching the friction material to the back plates to create a complete brake pad assembly. The friction material is typically bonded to the back plates using a high-strength adhesive that can withstand the forces and temperatures generated during braking.

In conclusion, the process of manufacturing brake pads steel back plates is a complex and precise operation that requires careful attention to detail and quality control. From procuring raw materials to stamping, heat treating, coating, and final assembly, each step in the manufacturing process plays a crucial role in creating high-quality back plates for brake pads. By following strict manufacturing standards and quality control procedures, factories can ensure that their brake pads steel back plates meet the stringent requirements of the automotive industry.